Pitch to the Problem

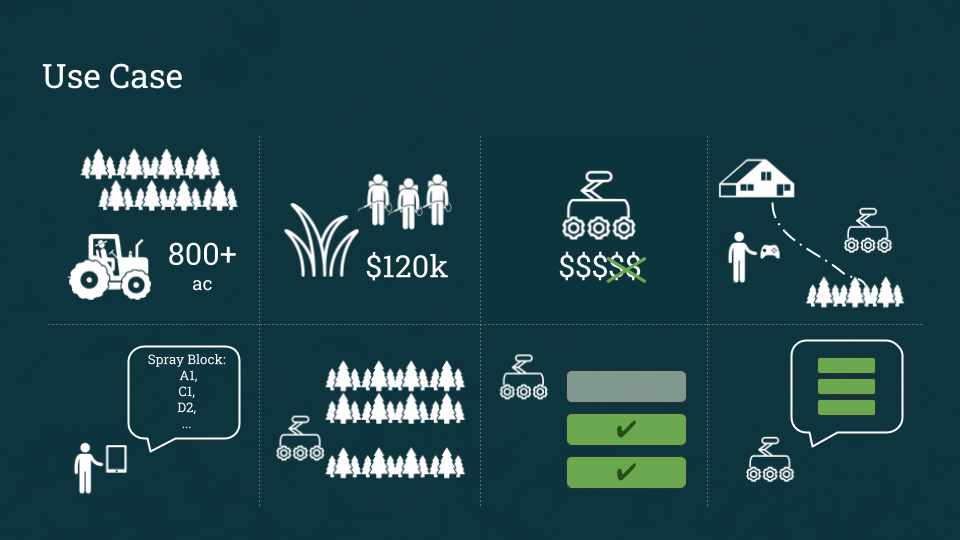

Imagine if you were a nursery farmer with 800 acres of land and this peak season you can only find 10 extra workers to move and sell your inventory, which is not enough to even move half your stock. With the price of labor increasing every year, how do you find cheap and reliable labor for the next 5 years? This is where we think robots can help.

We are developing a small robot that can drive between narrow rows and spray around the farm autonomously so that workers can do more important work and farm owners can save cost and time. For millions of farmers who grow plants in narrow rows, we can help them save 30% cost every year on just the herbicide-spraying task.

User story

Tom is a pot-in-pot farmer from Tennessee who has a huge nursery of different kinds of trees spanning 800 acres. Spraying herbicide on his farm currently costs him 4000 man hours and $100,000 annually. He wants to automate this process by using a robot that can spray between rows of trees with minimal human involvement. He just received the spraying robot developed by Squirtle Squad, promised to reduce his labor costs by zzz. Since Juniper trees are his most profitable and widespread crop, he wants to use this robot to target this area of his farm first. He asks his foreman to drive up to the Juniper plantation and use the robot tomorrow.

In the morning, at the start of his shift, the foreman loads up the charged robot and controller in his car. He unloads the robot and uses the controller to drive it to the herbicide refilling station, also known as the base station, near the Juniper plantation. After filling up the herbicide, he sends the robot an ordered list of tree blocks it has to cover using a web interface. The robot drives autonomously from the base station to the start of the first block and positions itself in the start of the first row of the block. The robot detects that it is inside a row, turns on its sprayer, and moves forward while staying centered between the rows of Juniper trees on either side. Once it reaches the end of the row, it senses that it has to turn to enter the adjacent row so the robot turns off its sprayer and makes a U-turn, and enters the next row.

The robot continues its spraying operation until it reaches the end of a block of trees. The foreman can monitor the robot operation remotely and receive notifications if there are any issues with the normal operation, allowing the foreman to focus on his other tasks. The robot leaves the sprayed block and goes to the next block of trees, enters the closest row and repeats the spraying as before. Once it has finished spraying on the last block of trees it returns to the base station and notifies the user that it has finished its objective. The foreman comes back to the base station to retrieve the robot, drives it back to his vehicle, and returns back to the office.