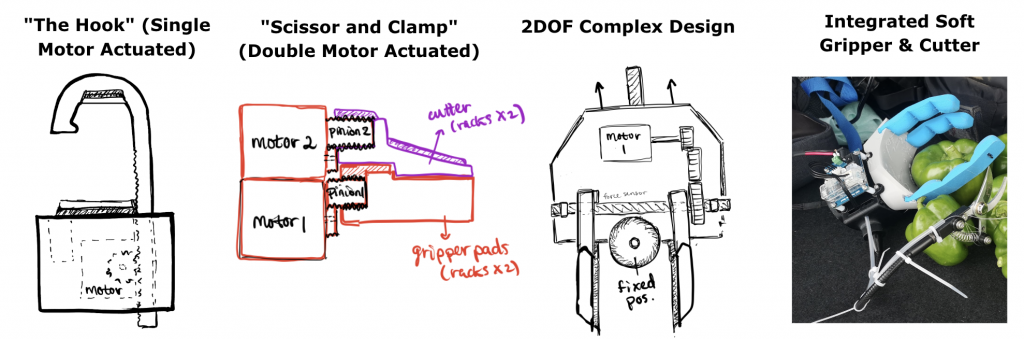

In determining the desired functionality of the end-effector, high-level concepts were brainstormed and sketched, shown in the figure above. The first design, “the hook”, pulls the peduncle towards the end effector, cutting it with a guillotine-type motion, and clamping the pepper side with high friction pads located directly under the blade. The second design, the “scissor and clamp”, has two motors which separately clamp and cut the pepper stem. The third design, the “2DOF complex design,” adds an additional degree of freedom, pulling the gripped peduncle and cut location of interest away from the plant and passing it through a rotary blade, reducing the risk of harming the plant or other peppers in the vicinity. Finally, the fourth concept is based on the previous prototype developed in Professor Pollard’s lab. It involves a tendon-actuated soft gripper which could be retrofitted to add at least one degree of freedom in the cutter location.

Initial field tests revealed that the soft gripper design did not perform well due to the variability of pepper orientations and unstructured nature of the plant. For example, peppers may grow upside down or behind other stems. The bulkiness of the soft gripper makes it difficult to maneuver through the density of the plant. Additionally, after placing the gripper on the pepper, at least three degrees-of-freedom would be needed to move the cutting device to the peduncle. Therefore, separately gripping the pepper and then cutting the peduncle may not be the most effective solution. Instead, directly gripping the peduncle itself reduces the required degrees-of-freedom needed to extract the pepper and provides increased maneuverability.