Spring Semester

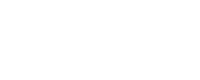

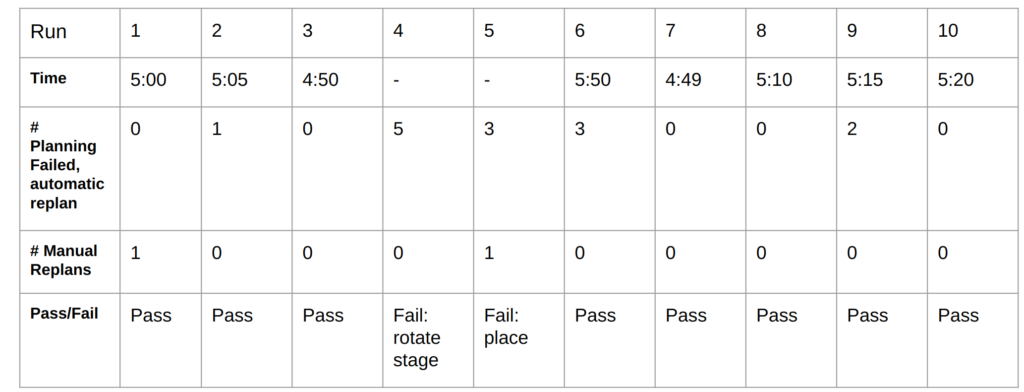

To verify the reliability of our motion planning system, we did a series of runs in Gazebo simulation and real hardware. We recorded the time to execute policy, the number of automatic replans, the number of manual replans triggered by the user, and whether it passed or failed. If it failed, we reported why it failed. The goal was to pass 4 out of 5 runs and we have met that goal in both real and sim.

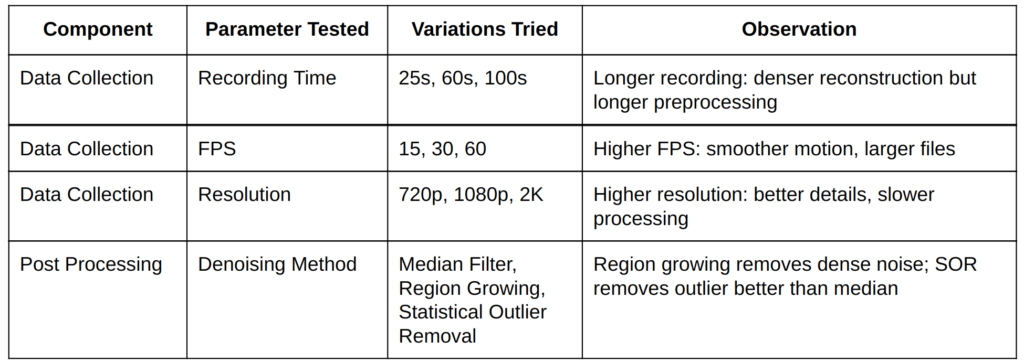

On the perception side, we did some data collection to see what the best parameters would be for the pipeline. The conclusion was:

- 15 FPS @ 1080p for 60s → fastest pipeline without loss in reconstruction quality

- Median filtering (frame-to-frame) + SOR (final output) → best denoising with calibrated camera

Fall Semester

We ran a series of stress testing on the manipulation subsystem to explore the initial object pose limitations of where the arms are able to plan within the constrained workspace. The table below shows the different x and y positions as well as yaw angles that we tried. We found that the arms are successful when the object are place in the (0,0) position +/- 5 cm and the yaw angle range was between 35 to 60 degrees.