Electrical Subsystem/ PCB design

The following is an outline of the electrical subsystem of GRASP and the power distribution PCB.

For our hardware system, as a proof of concept for our Reinforcement Learning (RL) estimation

algorithm, will be mainly a cart equipped with a perception system and geared with manual control

for the mobility. We are planning to use an uninterruptable power supply as our main power supply,

which is connected to a transformer to step down the voltage to a constant 12V supply for the

power system PCB. The power system serves as a hub to monitor the voltages to the subsystems,

which are now planned to include a Lidar sensor, an IMU sensor, and a camera sensor. And

currently, with the main focus of the project on the viability of the algorithm and the fact that we

are using a simulated environment, we are not planning to perform highly accurate localization and

control design in the physical hardware.

We are using the uninterruptable power supply with its silent, fast, and stable feature. But

if that is not available, we could easily replace it with a Li-Po Battery for a 12V voltage input to the

power system PCB. Furthermore, for the IMU and Camera sensor, we are using the

RealSense T265 which couples both sensors in a single unit. A detailed description of the

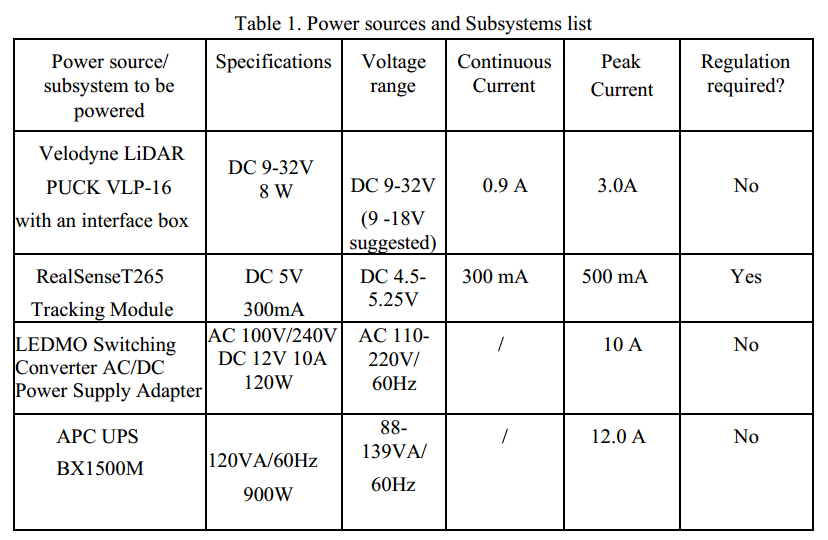

subsystem and the power source including voltage range, continuous current, the regulation

requirement is listed in the following table:

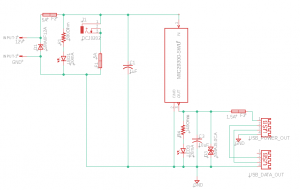

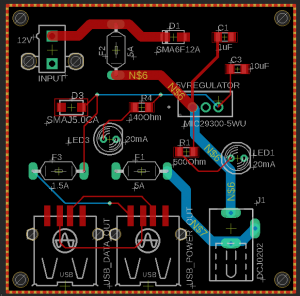

With the above table, the PCB board was designed to act as a power distribution unit which regulates the power supply for each

subsystem with details as listed below. With the schematic and board shown in Figure 1, we could satisfy the power needs for each of the

subsystems with over/reverse voltage protection.

• Lidar subsystem: For the Velodyne Puck-16 sensor, we have an interface box comes with it.

The interface box provides the over/reverse voltage and accepts 9V to 18V DC voltage. The

overvoltage is triggered at 32V and blows the 3A automatic blade fuse inside the box. Thus,

we are not providing any regulator for the Lidar subsystem due to the fact that our 12 V

input will work just fine.

• Camera/IMU T265 subsystem: For the T265 sensor, 5V DC voltage is expected. We

decided to use the MIC29300-5 regulator to provide the required voltage. MIC29300-5

takes an input voltage ranging from -20V to +60V, where our 12V DC input could fit

comfortably. The current rating of MIC29300-5 is 3A which satisfies our peak current

requirement for the T265, which is 500mA. We have also provided over voltage/current

protection with a transient voltage suppressor (SMAJ5.0) and a 1.5A fuse, which will blow

at 150% of the operating current.

Figure 1: Power distribution board schematic and board layout

Further design concerns and mounting plan could be found at the mounting plan file attached below:

TeamD_PDS_schematic_design

TeamD_PDS_conceptual_design

TeamD_PDS_mounting_plan