Problem Description

Koppers, a global chemicals/materials company and the leading US-based producer of railroad ties is commissioning a state-of-the-art facility in North Little Rock, Arkansas. Part of the production process for wood ties involves treating the material with the chemical compound creosote.

After treatment, the ties are then left to dry out, which results in creosote dripping on top of metal planes (also known as drip pans). This dripped liquid was then supposed to flow toward the grates installed for the purpose of collecting it.

However, an insufficient slope on the dripping platforms, coupled with the high viscosity of creosote, prevents the chemical from correctly flowing to the disposal collectors, which results in an accumulation of disposable material. During construction, these slopes were tested using water, but their low viscosity compared to creosote led to the inaccurate conclusion that creosote would also flow well.

As of now, the problem is being dealt with by having a human operator enter the production line and manually, with the help of a chemically resistant squeegee tool, force the accumulated chemical towards the collection grates. Once there is enough “pull”, a flow can be obtained. While this is a working solution, safety requirements stipulate that production stops whenever a human is present in the area. This is enforced via the gates: whenever these gates are open, it means a person is present and production automatically shuts down. These shutdowns – which happen with a frequency above what should be desired, since the chemical accumulates fast – cost Koppers significant hours in production.

As a possible alternative, the sponsor has suggested the use of an autonomous system to perform the cleaning. Using such a system would prevent production from stopping as often, as the need for a human operator would be greatly reduced. That is precisely what our team will do!

Use Case

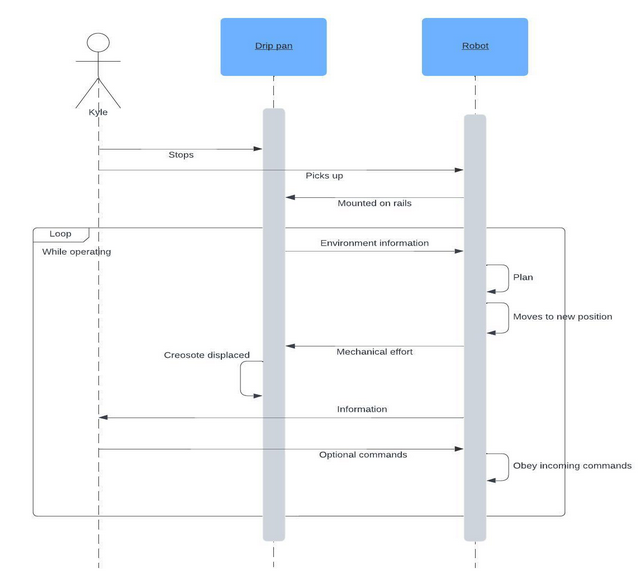

Our system aims to be efficient, reliable and user-friendly, thus enabling our sponsor to fulfill their operational requirements. With our solution, the user only has to stop factory operations once: to load the system onto the pan. From there, with the drip pan operating normally, our system can move itself to new positions, sense the environment, detect creosote and pull it towards the drain, all while keeping a lookout for user commands.

Simple, Safe and Successful: that is CreoClean!