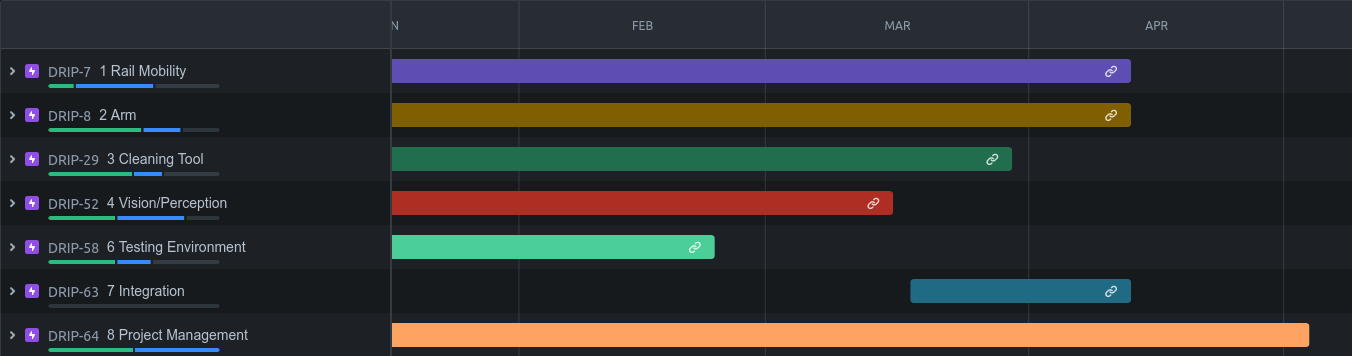

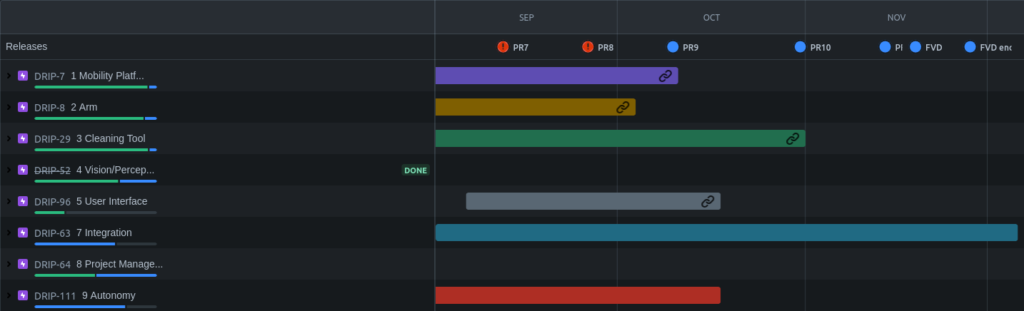

Schedules

Progress Reviews Presenters

Spring:

- Leonardo Mouta Sensors and Motor Lab [8th February 2024]

- David Hill Progress Review 1 [15th February 2024]

- Yatharth Ahuja Progress Review 2 [29th February 2024]

- Louis Plottel Progress Review 3 [21st March 2024]

- Michael Gromis Progress Review [4th April 2024]

- David Hill Power Distribution System PCB Lab [9th April 2024]

Fall:

- Louis Plottel Progress Review 7 [11th September 2024]

- Michael Gromis Progress Review 8 [25th September 2024]

- Yatharth Ahuja Progress Review 9 [9th October 2024]

- Leonardo Mouta Progress Review 10 [30th October 2024]

- David Hill Progress Review 11 [13th November 2024]

Gantt Chart of Development Schedule

Test Plan

Link to our full Spring test plan.

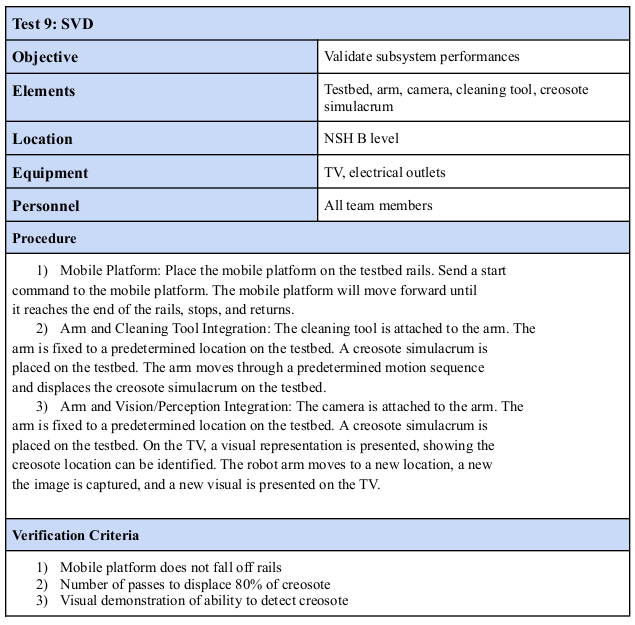

Highlight of our Spring Validation Demo (SVD):

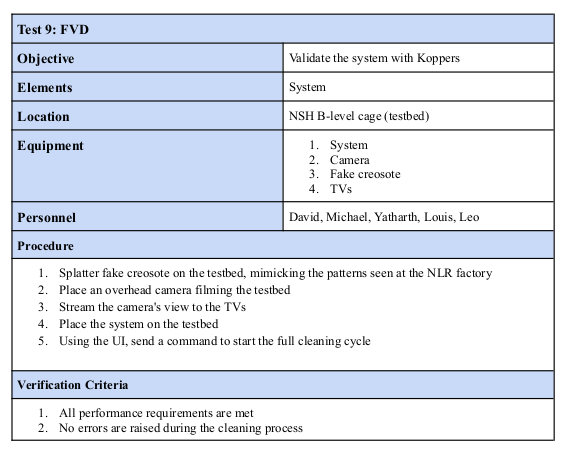

Link to our full Fall test plan.

Highlight of our Fall Validation Demo (FVD):

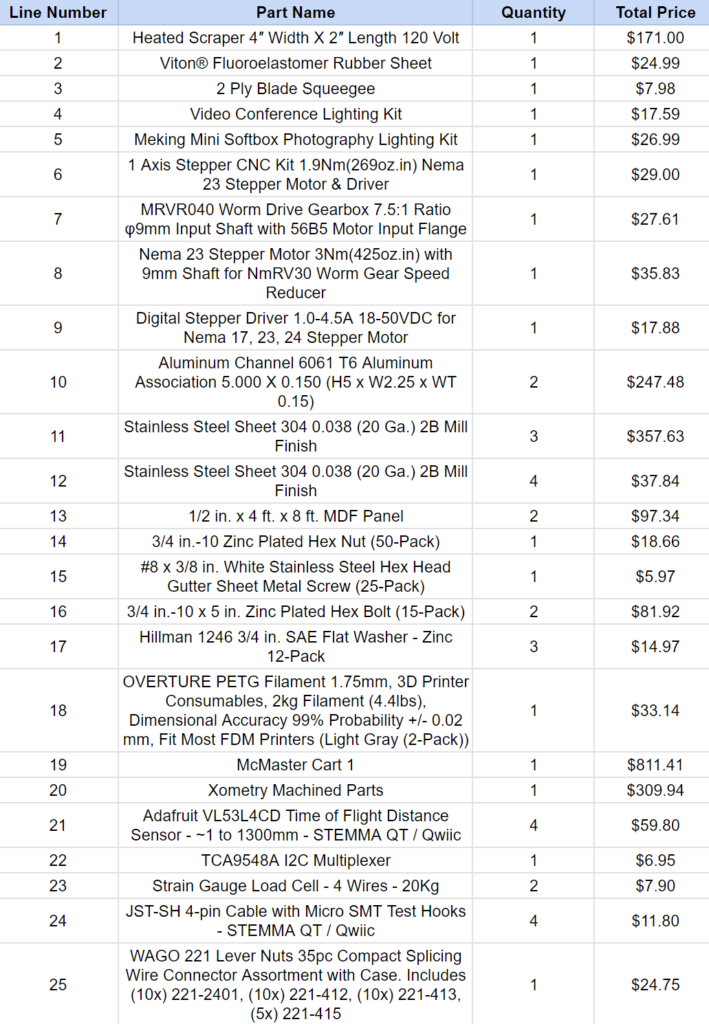

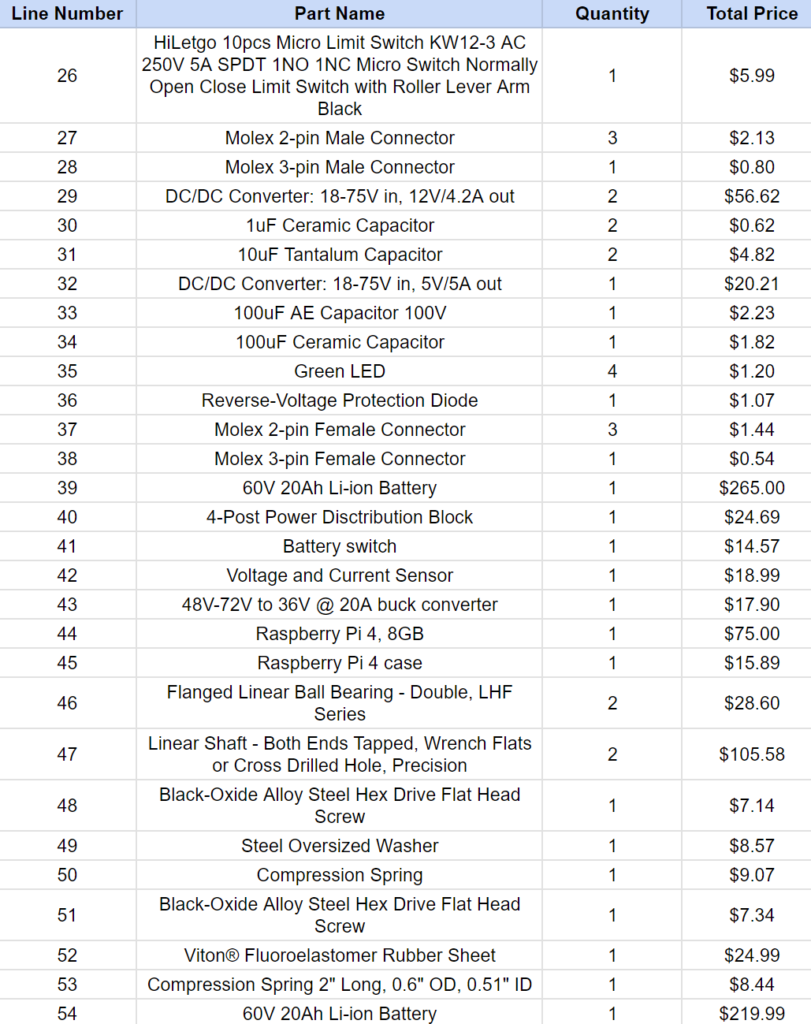

Parts List

Issue Log

| Number | 1 |

| Date Initiated | Oct-2023 |

| Date Resolved | Nov-2023 |

| Participants | yahuja, mgromis, dhill, lmoutape, lmplotte |

| Description | Decision on which platform to use for the system |

| Options | Robotic arm on rails, mobile arm on dp surface, humanoid robot on factory floor |

| Resolution | Settled on robotic arm on rail |

| Justification | Simplest platform to implement that still allows us to achieve the mission objectives |

| Number | 2 |

| Date Initiated | Feb-2024 |

| Date Resolved | Feb-2024 |

| Participants | yahuja, mgromis, dhill, lmoutape, lmplotte |

| Description | Decision on how to handle arm delay |

| Options | Change platform concept, focus on simulation, get another arm |

| Resolution | Settled on focusing on simulation |

| Justification | This path allows us to continue working until arm arrives, without forcing us to change our design or spend more money |

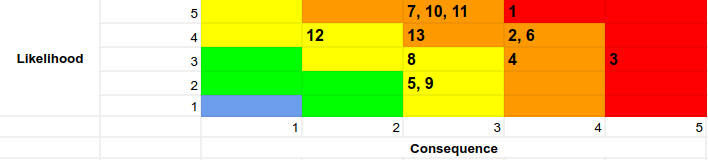

Risk Management

| ID | Risk | Req | Type | Likelihood | Consequence | Mitigation |

| 1 | Robot arm may not fit within budget | NF4 | Cost | 5 | 4 | Ask Koppers to buy the arm |

| 2 | Delivery of arm is delayed | N/A | Schedule | 4 | 4 | Order components early |

| 3 | Arm integration with cleaning tool not able to clean creosote in practice | F5 | Tech | 3 | 5 | Test frequently |

| 4 | System damages the drip pan | NF3 | Operation | 3 | 4 | Include safety features |

| 5 | Someone from Koppers leaves | N/A | External | 2 | 3 | Keep detailed documentation |

| 6 | Need a strong linear actuator for heavy arm | F4 | Tech | 4 | 4 | Design requirement |

| 7 | Hard to know all lighting conditions in factory | F2 | Tech | 5 | 3 | Test with different light conditions |

| 8 | Need to keep camera clean from creosote | NF5 | Tech | 3 | 3 | Design |

| 9 | Koppers not ok with a camera in their factory | N/A | Operation | 2 | 3 | Ensure camera does no recordings |

| 10 | Missing drawings | N/A | External | 5 | 3 | Contact sponsor for full tech drawings |

| 11 | Cannot send torque commands to the robot | F5 | Tech | 5 | 3 | Add linear elastic actuator for precise force control |

| 12 | Camera is EOL, support ending | N/A | Tech | 4 | 2 | May need to buy a new camera or use older software |

| 13 | Depth sensing bad with current camera | F5 | Tech | 4 | 3 | Check other alternatives |