The ADD_IN team aims to develop a 3D printer technology (named 4DOF) capable of producing printed parts which incorporate commercial off the shelf (COTS) components. These COTS items can include components such as threaded inserts, structural reinforcement (stiffeners), and electronics. Incorporating these components enables inclusion of geometrically precise features (such as threads), production of stronger parts (via the use of stiffeners), and reduced overall production time (since post-printing operations such as tapping and gluing can be eliminated).

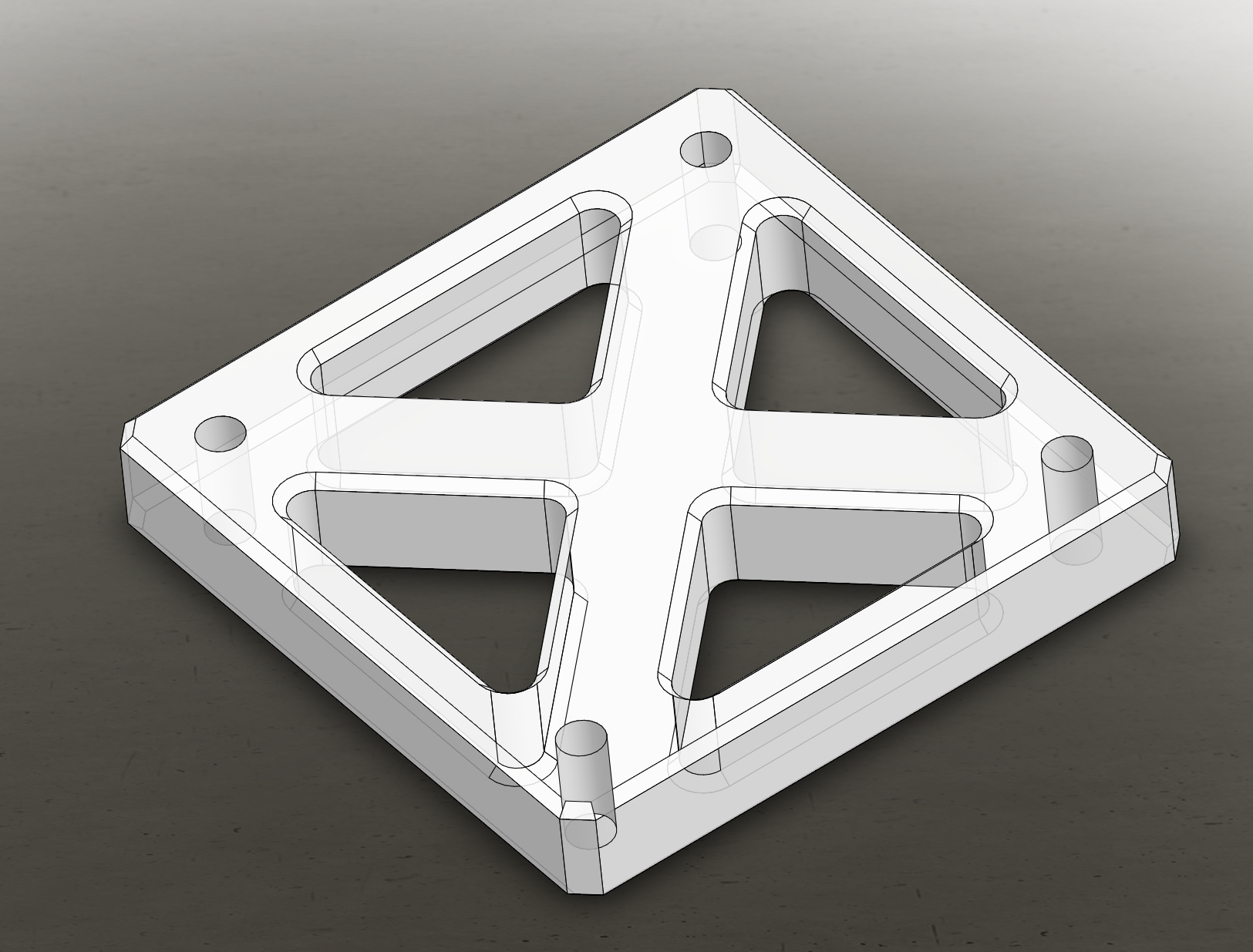

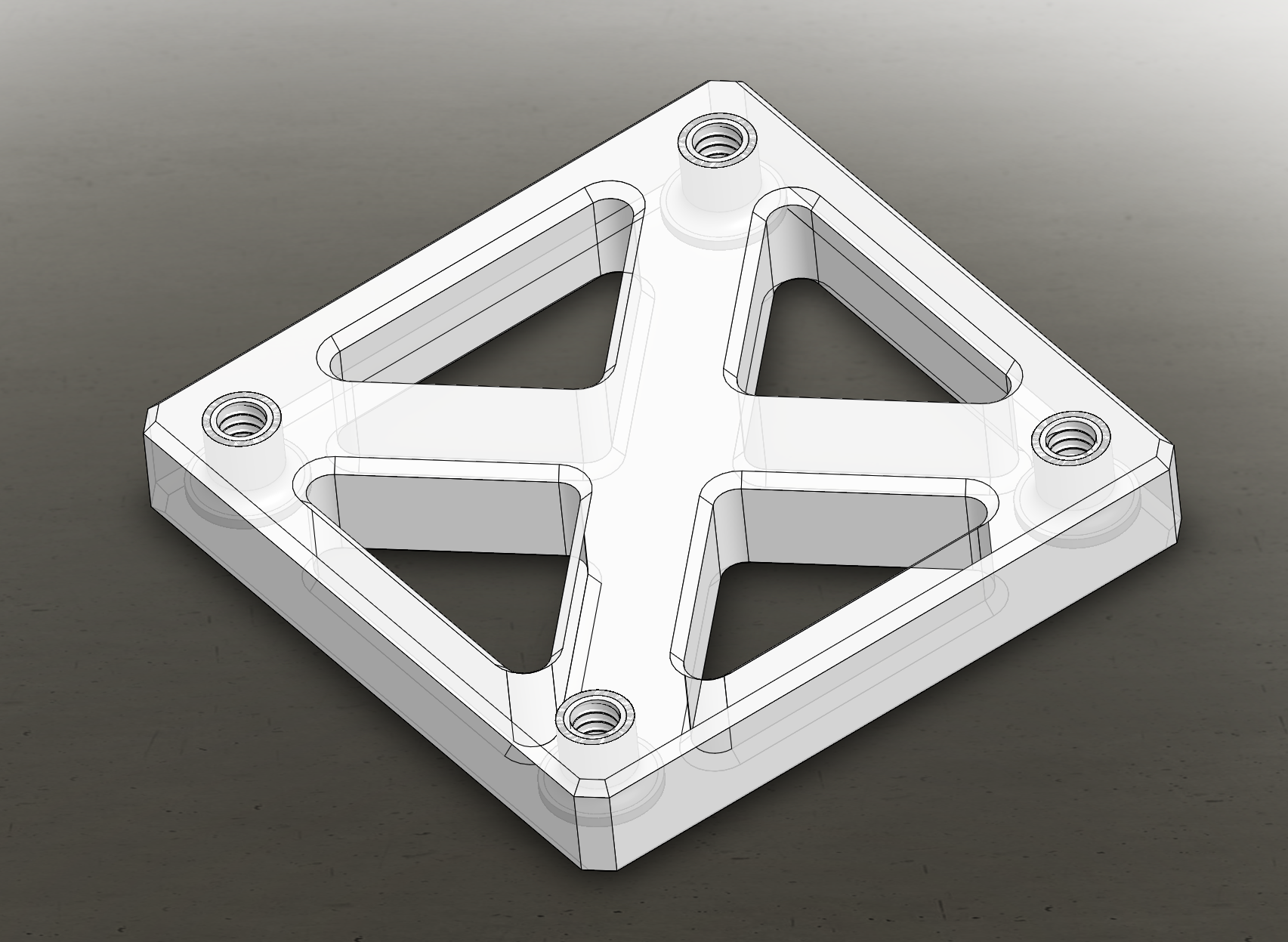

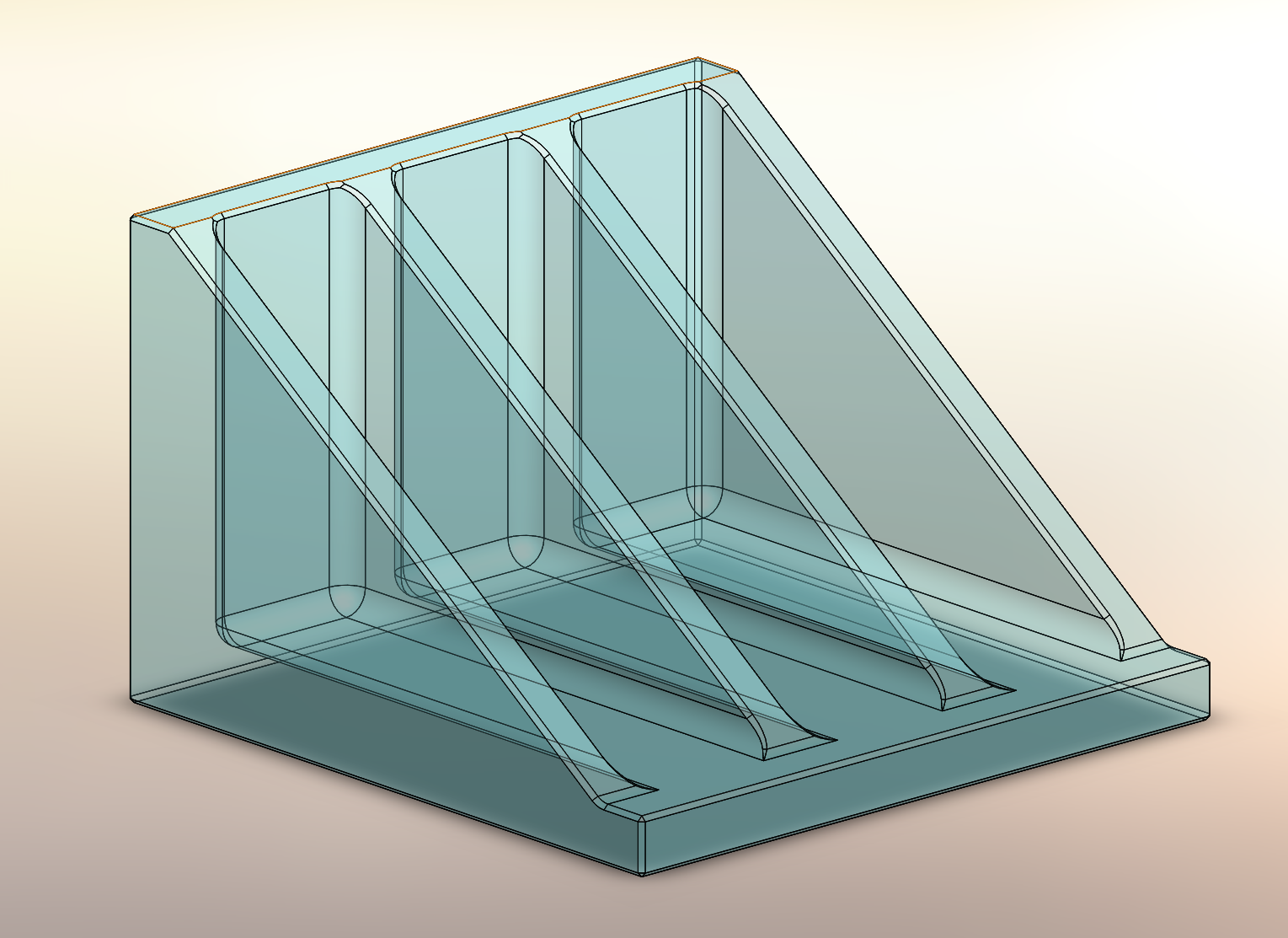

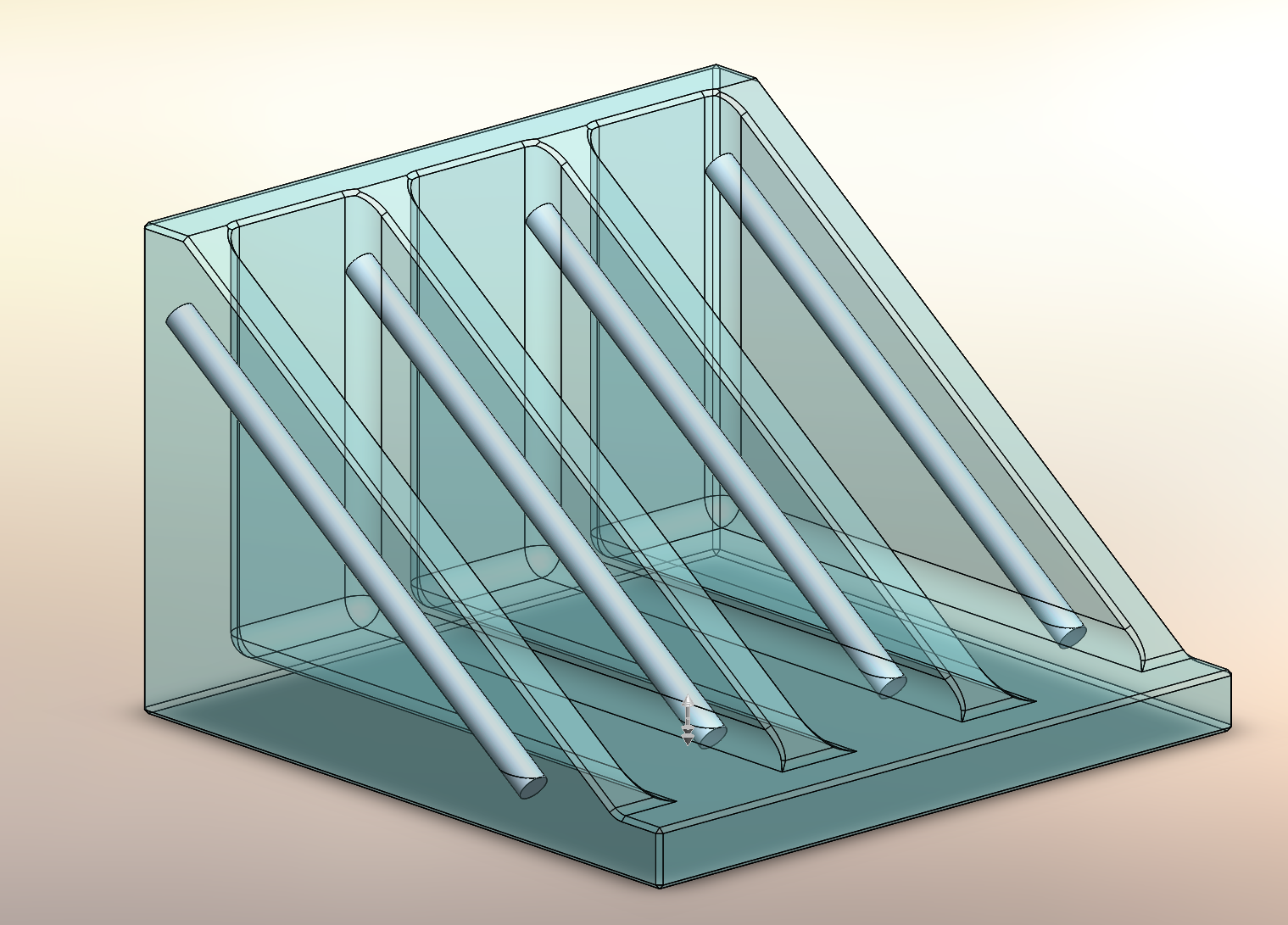

Some examples of of possible uses of the 4DOF printer are exhibited below:

Before After

The parts to be incorporated will be generally cylindrical or rectangular prism in shape, can optionally extend up to 1” above the top layer of the part, and must have sides which are orthogonal to the print surface. The 3D print material will be precisely deposited along the perimeter of the COTS item, thus encapsulating it within the 3D printed part.

Within the scope of this project, the installation of COTS parts during the printing process will be performed by a human operator. When the 3D printer reaches the print layer on which a part is to be installed, it will ‘pause’, move to a safe and accessible configuration for COTS item insertion, and await a command from the user that the part has been successfully installed before resuming printing. The system will be able to produce printed parts incorporating multiple COTS items at varying locations and orientations, provided that the orientations and clearances between the parts do violate certain geometric restrictions.