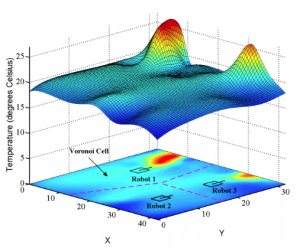

Figure 1. Graphical depiction of system design using cyber-physical architecture

The entire system is composed of three subsystems: (i) a Master Computer that maintains and updates the temperature distribution model, as well as decides the next sample location for every individual agent based on their capabilities, (ii) an Unmanned Aerial Vehicle (UAV) subsystem consisting of one or multiple aerial robots, and (iii) an Unmanned Ground Vehicle(UGV) subsystem composed by one or multiple ground robots.

Master Computer

Temperature Model

Given multiple temperature samples at different discrete locations, the master computer manages to provide a continuous distribution model for the temperature within the required area.

Figure 2. Example Temperature Gaussian Mixture Model

Per the sponsor’s requirement, the specific model is selected to be the Mixture of Gaussian Mixture Models [10]. A typical example is shown in Figure 4. It demonstrates a good generalization of environmental modeling, especially for temperature modeling.

Interest Point Identification Algorithm

Current temperature model needs updating until converge. The next points at which the Master Computer wants the robots to take temperature are determined by interest point identification algorithm. The master computer applies Upper Confidence Bound algorithms to select the next interest points, which would give the most temperature information according to the current model. The upper confidence bound is determined the sample noise as well as the number of times sampled before. The higher the upper confidence bound for interest point, the more accurate the model will be after the temperature samples are taken.

Interest Point Allocation Algorithm

After the interest points are selected, Master Computer would assign those points to specific robots by interest point allocation algorithm. The major considerations are under robot’s mobility. For example, the Master Computer would assign the interest point above a ground obstacle to UAV considering the limitation of UGV’s mobility.

UGV Subsystem

Hardware

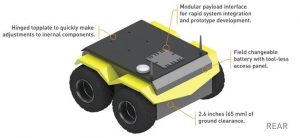

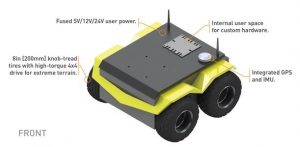

We will be using Jackal UGV for ground agent in the UGV subsystem throughout the project. Jackal is a fully integrated, lightweight and compact outdoor robot which provides a flexible platform for integrating sensors and utilizing its ROS API [1]. The machine is equipped with an Intel i5 onboard computer together with GPS and allows wireless connectivity via both Bluetooth and wifi [2]. It has an IP62 weatherproof casing and is rated to operate from -20 Celsius or +45 Celsius [2]. Additional to a Bumblebee stereo camera, a Velodyne VLP-16 LiDAR is also available onboard. According to the specification provided by Clearpath Robotics [2], the machine can handle a payload up to 20kg and with standard loads, the duration lasts for 4 hours.

Figure 3. Jackal UGV

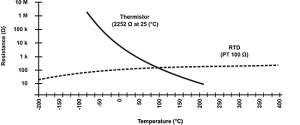

Additionally, we plan to install Negative Temperature Coefficient (NTC) sensors on the UGV agent. An NTC thermistor is a thermally sensitive resistor whose resistance exhibits a large, precise and predictable decrease as the core temperature of the resistor increases over the operating temperature range [5]. One desired feature of NTC sensors is that they experience a large change in resistance per Celsius, hence they have a much steeper resistance-temperature slope compared to other sensors (platinum alloy RTDs in Figure 8).

Figure 4. Bumblebee stereo camera [4] Figure 5. Velodyne VLP-16 LiDAR [3]

Figure 6. Thermistor performance characteristics [5]

The operating range of NTC spans from −55 °C to +200 °C, and the values of temperature sensitivities of NTC usually range from -3% to -6% per °C, depending on the specifics of the production process and the material used [5]. Considering our application, we plan to use glass encapsulated NTC thermistors. Encapsulating the thermistor in glass provide long-term stability and reliability for high-accuracy temperature sensing, as well as protecting the sensor during operation [5, 6].

Figure 7. NTC Thermistor[7]

Software

UGV’s Motion Planner receives the allocated interest point from the Master Computer. This interest point is then mapped into the task space and assigned as the target location. The Motion Planner then generates an obstacle-free trajectory from the current location to the target. We plan to deploy D* algorithm so that we can generate an optimal path while avoiding local obstacles.

We plan to use a PID controller to control the UGV motors and command the ground vehicle to follow the waypoints generated by the Motion Planner.

During the process of navigation, the State Estimation Algorithm keeps reading the LiDAR and GPS values to estimate whether the target location is achieved.

Once the agent arrives at the target sample location, it stops and measures the current temperature by interpreting the voltage on the NTC thermistor to temperature values. The temperature measurement is then forwarded to the Mater Computer.

UAV Subsystem

Hardware Platform

We will be using Intel AscTec Pelican UAV as the platform for the UAV subsystem. This platform contains an onboard computer with Intel® Core™ i7 processor. The quadrocopter offers plenty of space and various interfaces for individual components and payloads.[6] The LLP(Low-Level Processor) is the data controller, processes all sensor data and performs the data fusion of all relevant information with an update rate of 1 kHz. There is an onboard Hokuyo Laser Scanner with up to 30m range. The platform support varies of wireless communication links including Wifi and XBee (wireless serial).

Figure 8. AscTec Pelican UAV

Software

The navigation algorithm of UAV subsystem is similar to the software of UGV subsystems since they are playing a similar role. The detail of their control algorithms will be different due to the difference in their dynamic models.