System Status at the Progress Review #12 / 13

The full system implementation in Fall can be found here.

System Status at the Progress Review #11

Productivity measured from continuous simulation. (The video below is 4x speed)

System Status at the Progress Review #10

Continuous simulation running; robot heading to random goal points and forklifts following random recorded trajectories.

System Status at the Progress Review #9

We implemented the obstacle filtering feature that considers camera FOV and occlusions.

System Status at the Progress Review #8

We implemented Local A* as the nominal avoidance method. In the video, our robot moves towards waypoints and avoids collisions using local A*

We integrated pedestrians with our SVD factory environment(i.e. there are forklifts and our robot).

The predictive avoidance now can handle multiple types of obstacles; forklifts and pedestrians.

The predictive avoidance now can handle stationary dynamic obstacles. In the video, the forklift was moving and suddenly stopped, blocking the robot’s path to the next waypoint.

System Status at the Progress Review #7

We expanded our factory environment to have larger space for more entities.

We implemented pedestrian movement in the simulation with the help of existing pedestrian simulator ROS packages. Pedestrian models move between commanded waypoints repeatedly, avoiding collisions each other and with pre-defined obstacles; they are colored cuboids in the video below.

System Status at the Progress Review #5 / #6

The full system implementation in Spring can be found here.

System Status at the Progress Review #4

Path prediction and evasive plan generation

Our system can now predict the path of a forklift and plan an evasive maneuver. In the video below, the blue line is the expected path of the forklift, and the red line is the robot’s evasive plan(default is moving forward).

Scenario manager

We built a scenario manager to add noise to the initial condition of each scenarios.

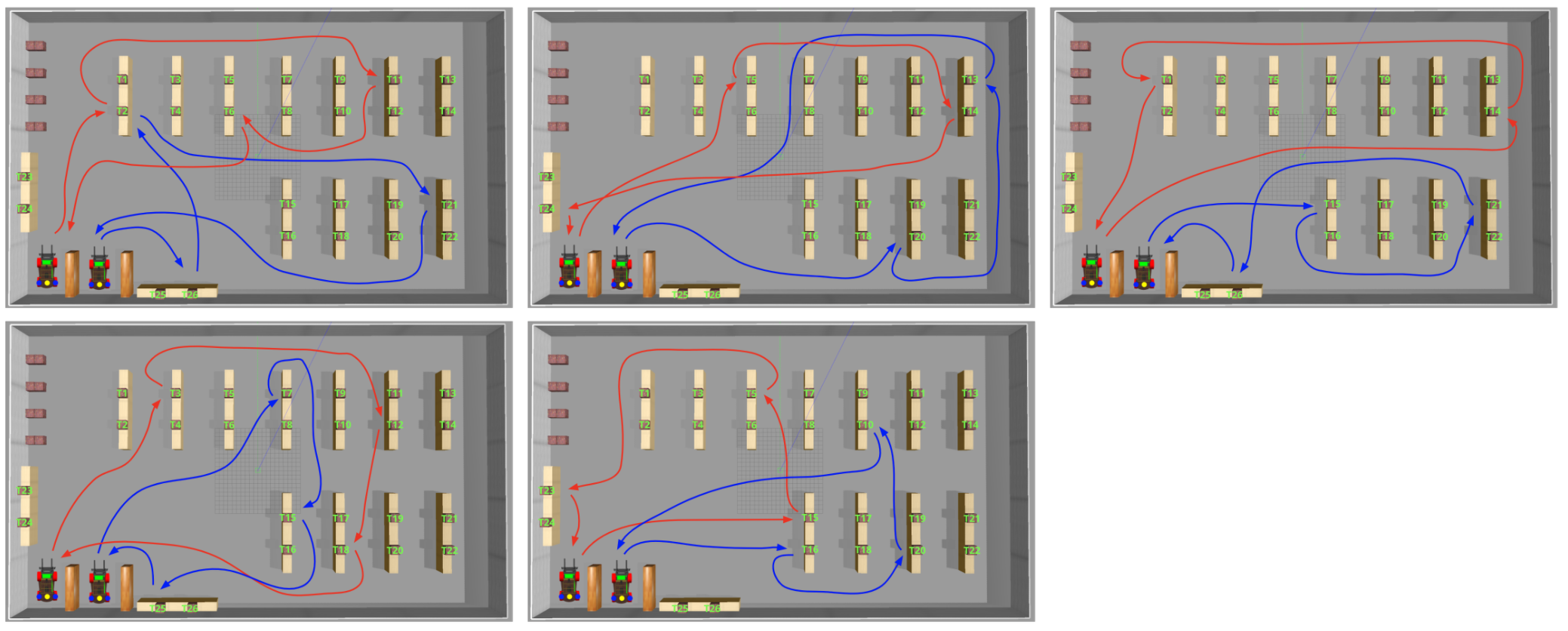

Forklift trajectory dataset and dictionary

We designed five task pairs and recorded more forklift trajectories based on that. Also, we built a trajectory dictionary storing these information.

System Status at the Progress Review #3

Forklift trajectory tracking

The virtual forklifts can now follow the recorded trajectories. In the video below, the forklift’s motion is being replayed as recorded.

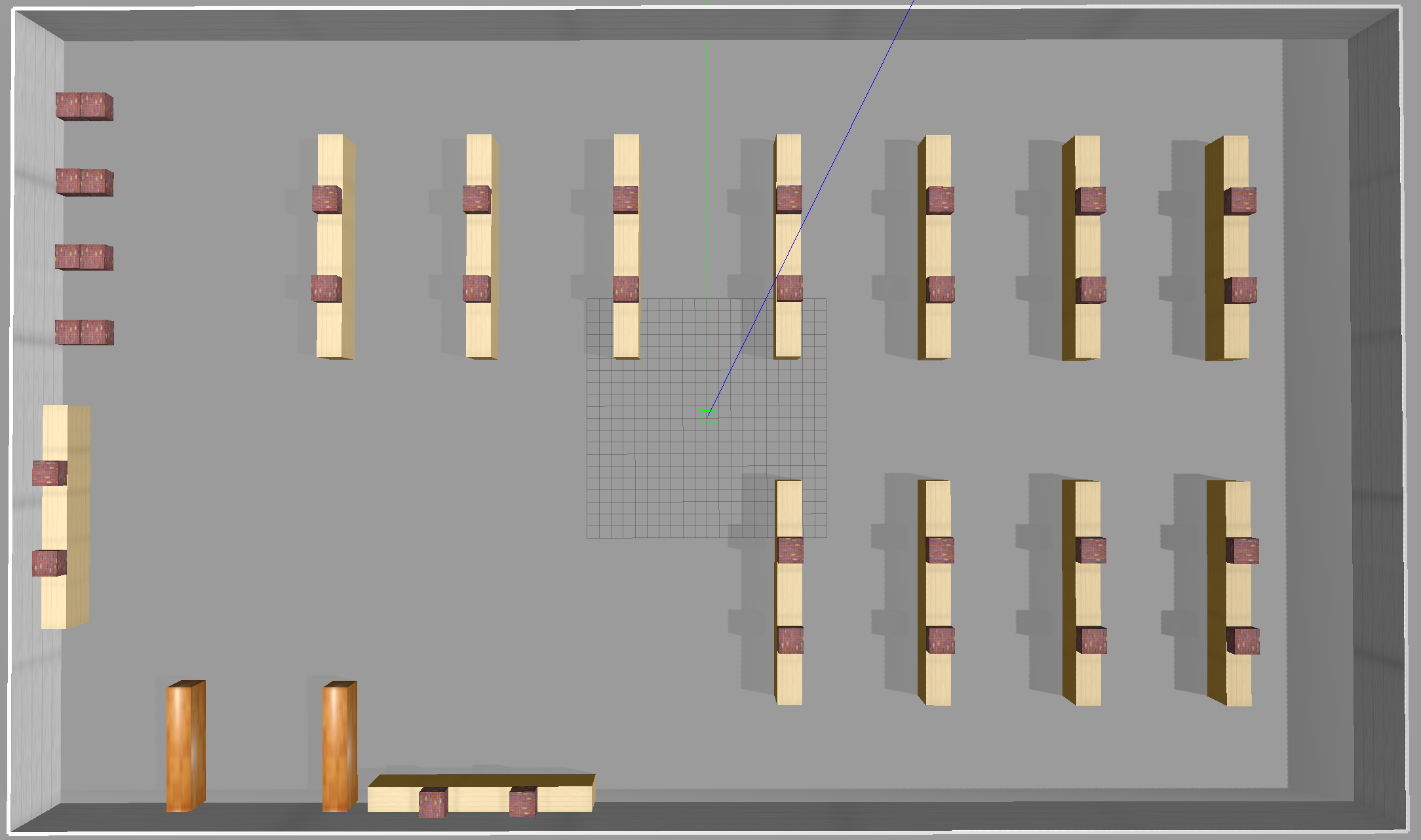

Full-scale factory environment

We built a simple full-scale factory environment (108m*64m) to show our system’s performance at SVD.

System Status at the Progress Review #2

Robot path following (Pure Pursuit)

Our virtual robot can now follow the path generated by the global planner.

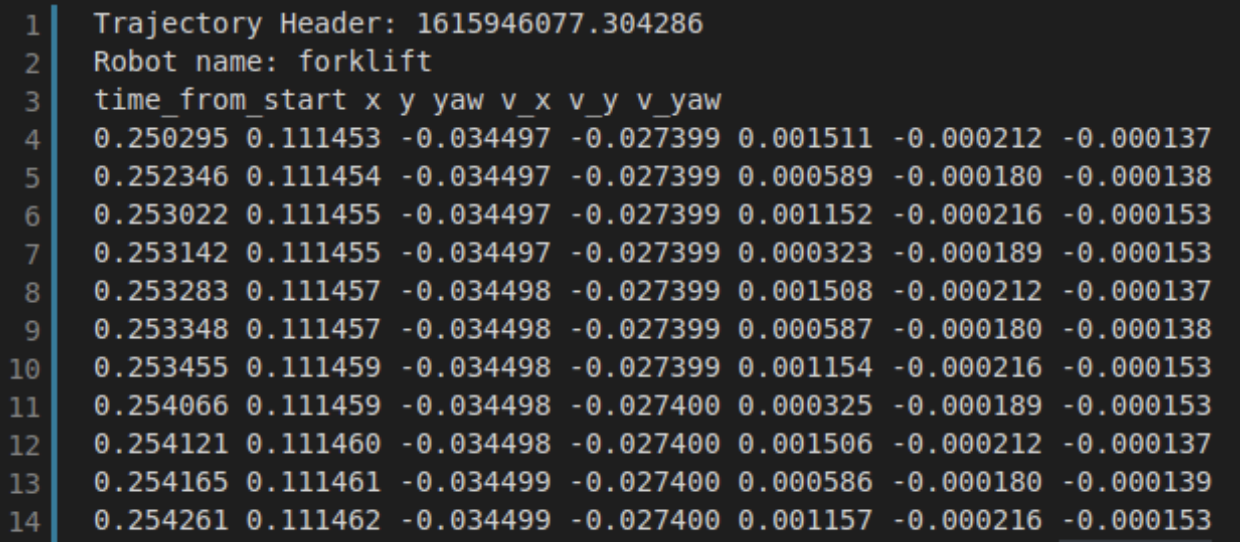

Forklift trajectory recording

With joystick controls, we moved the virtual forklift and recorded forklift trajectories needed to build a trajectory dictionary. This file contains the information of [time_stamp, x, y, yaw, v_x, v_y, v_yaw]

System Status at the Progress Review #1

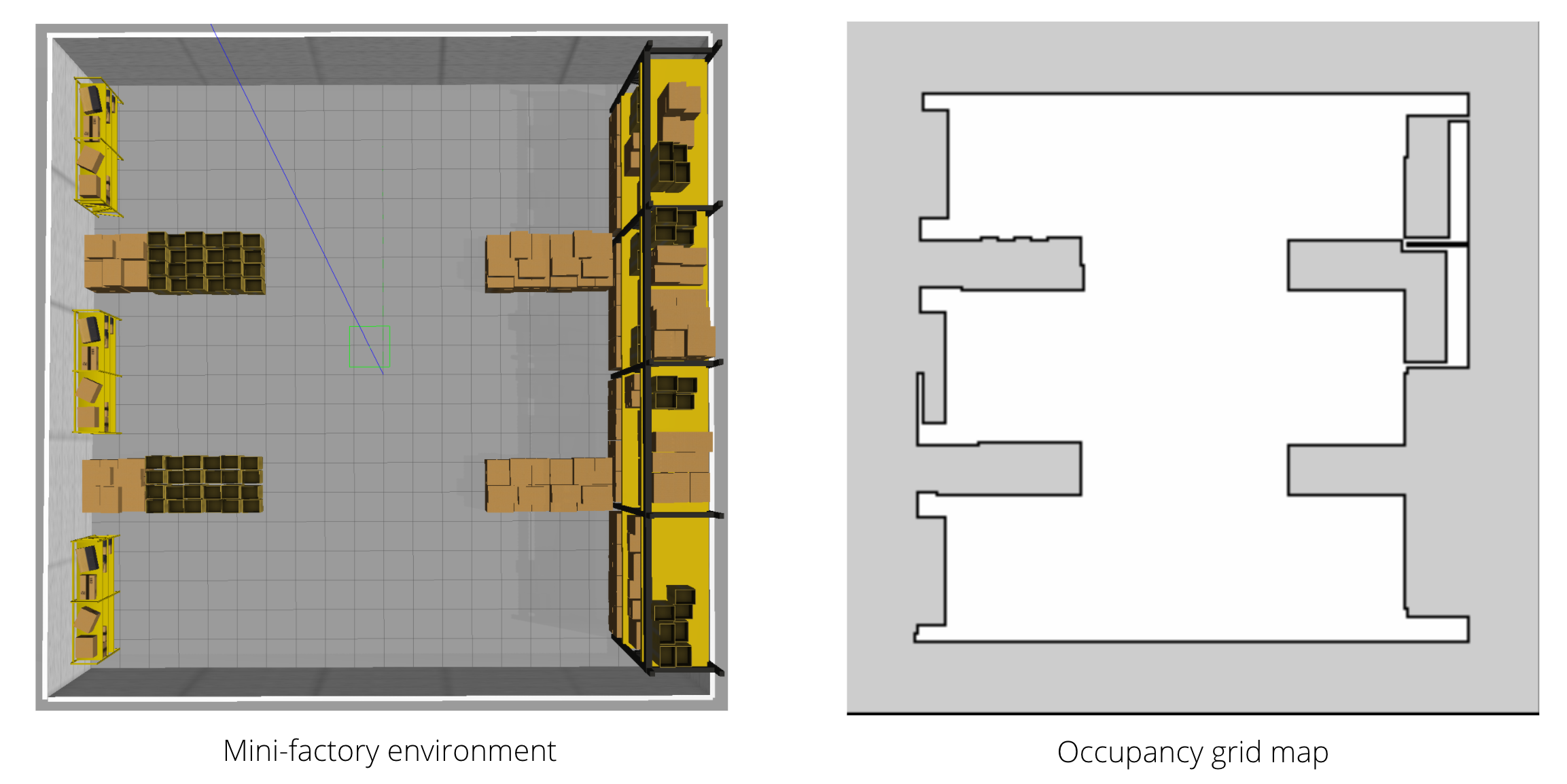

Mini-factory environment and occupancy grid map

We built this mini-factory environment (20m*20m) for the initial subsystem testing. The occupancy grid map shows open area (white) and occupied area (gray).

Global planner and cost map

We implemented the global planner generating paths with given waypoints.

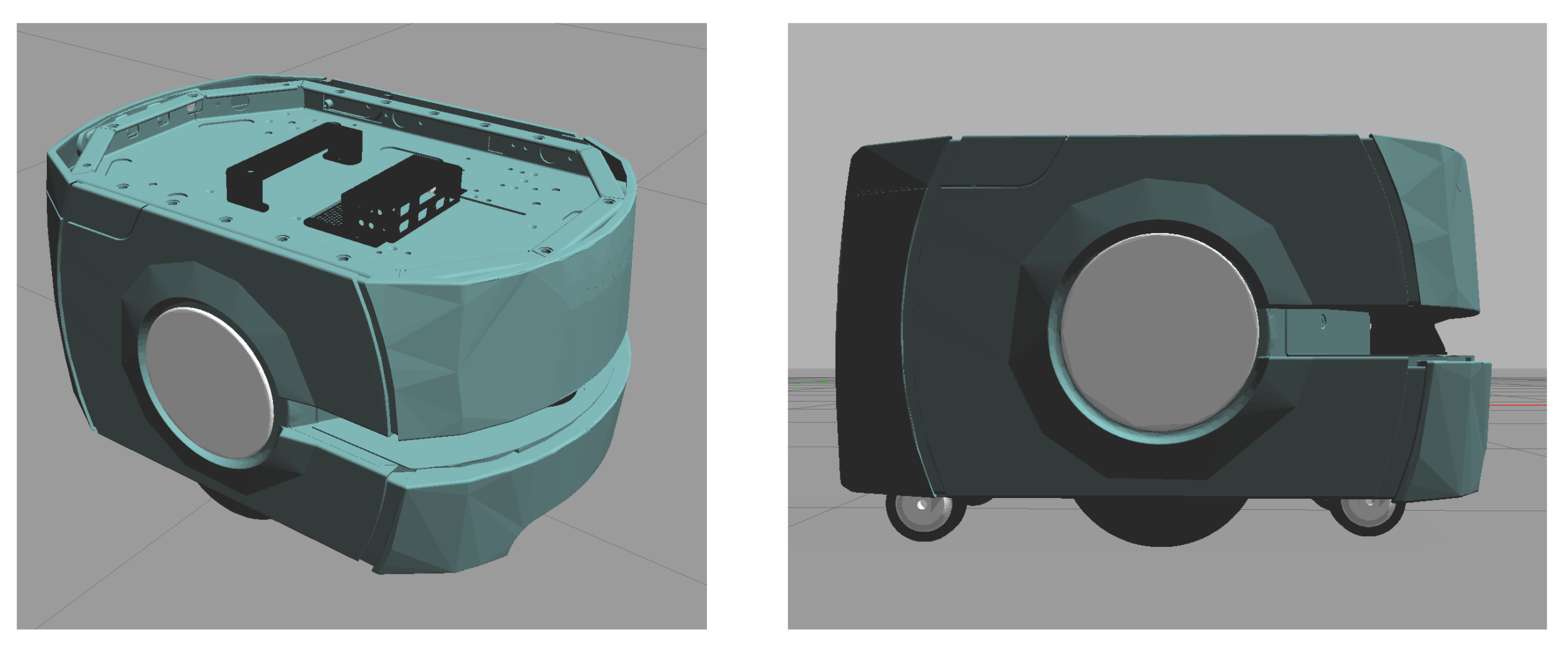

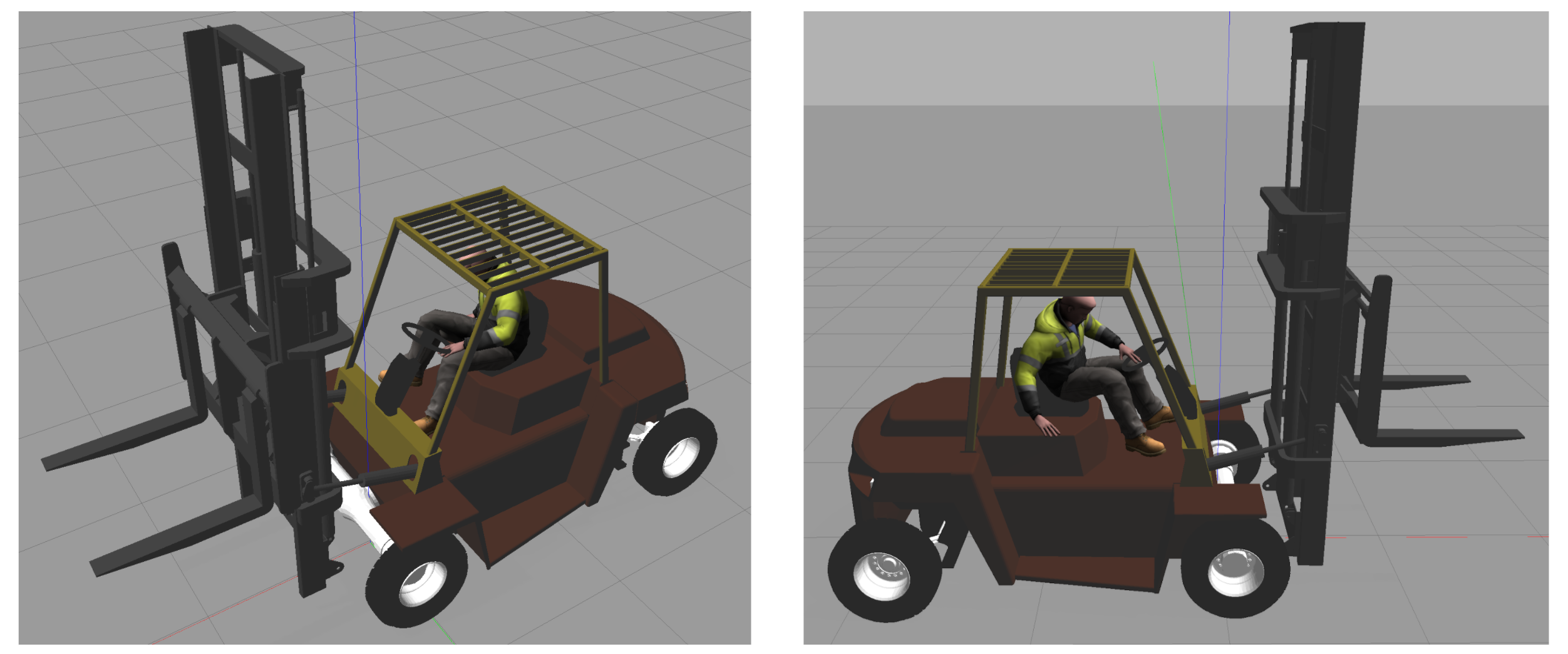

Virtual robot and forklift models

We created the virtual robot model (referenced to OMRON LD-60) and forklift model.