Fall 2021 (Up-to-date, Oct 4th)

Our test plan until FVD can be found here and 1-pager for FVD here

1-pager for SVD can be found here

Spring 2021 (Updated)

Fall 2021 (Updated)

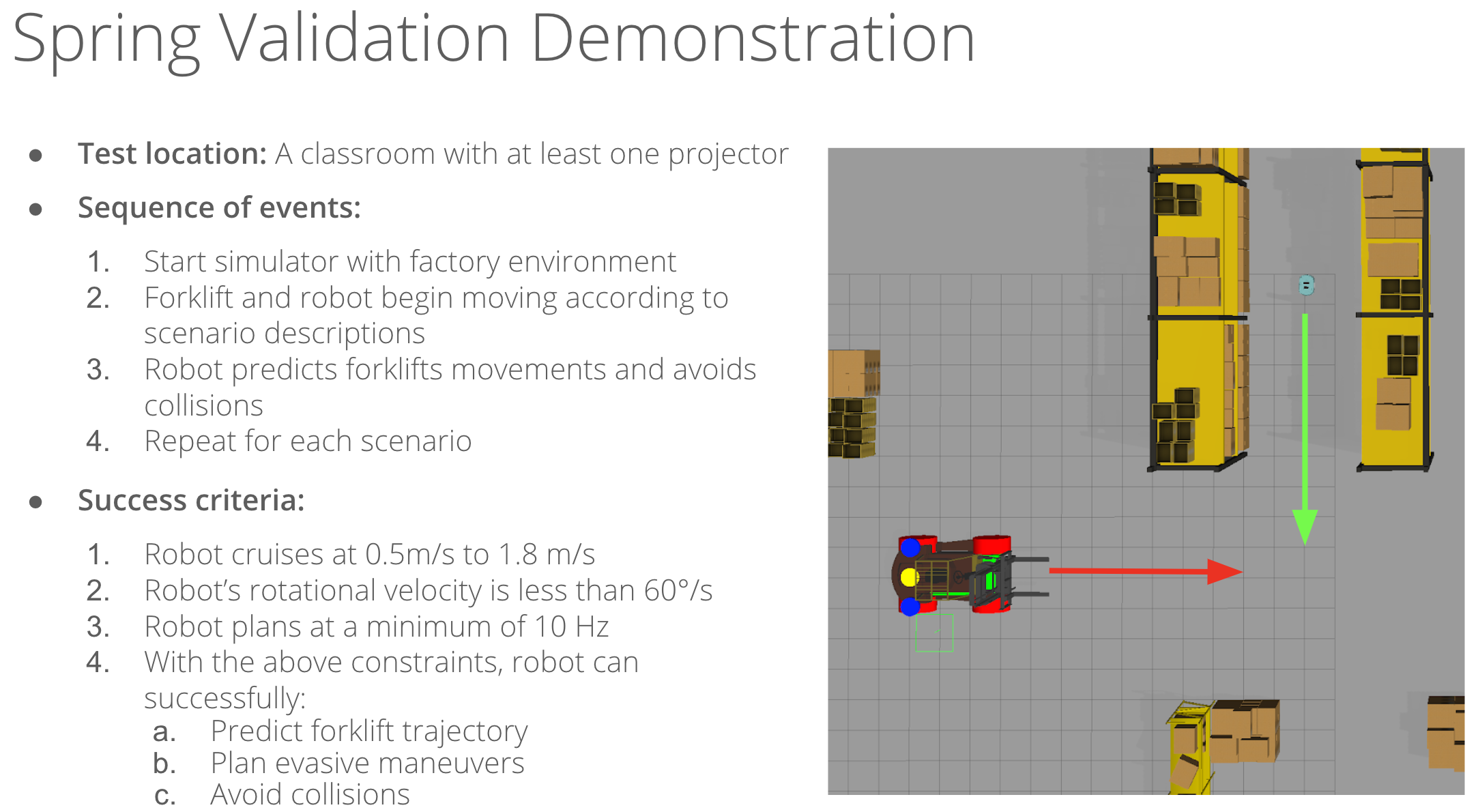

Spring 2021

Virtual System Validation:

A. Demo Conditions:

- Location: In simulation

- Equipment: A computer system or cloud server with Gazebo, ROS and COLA predictive avoidance packages installed

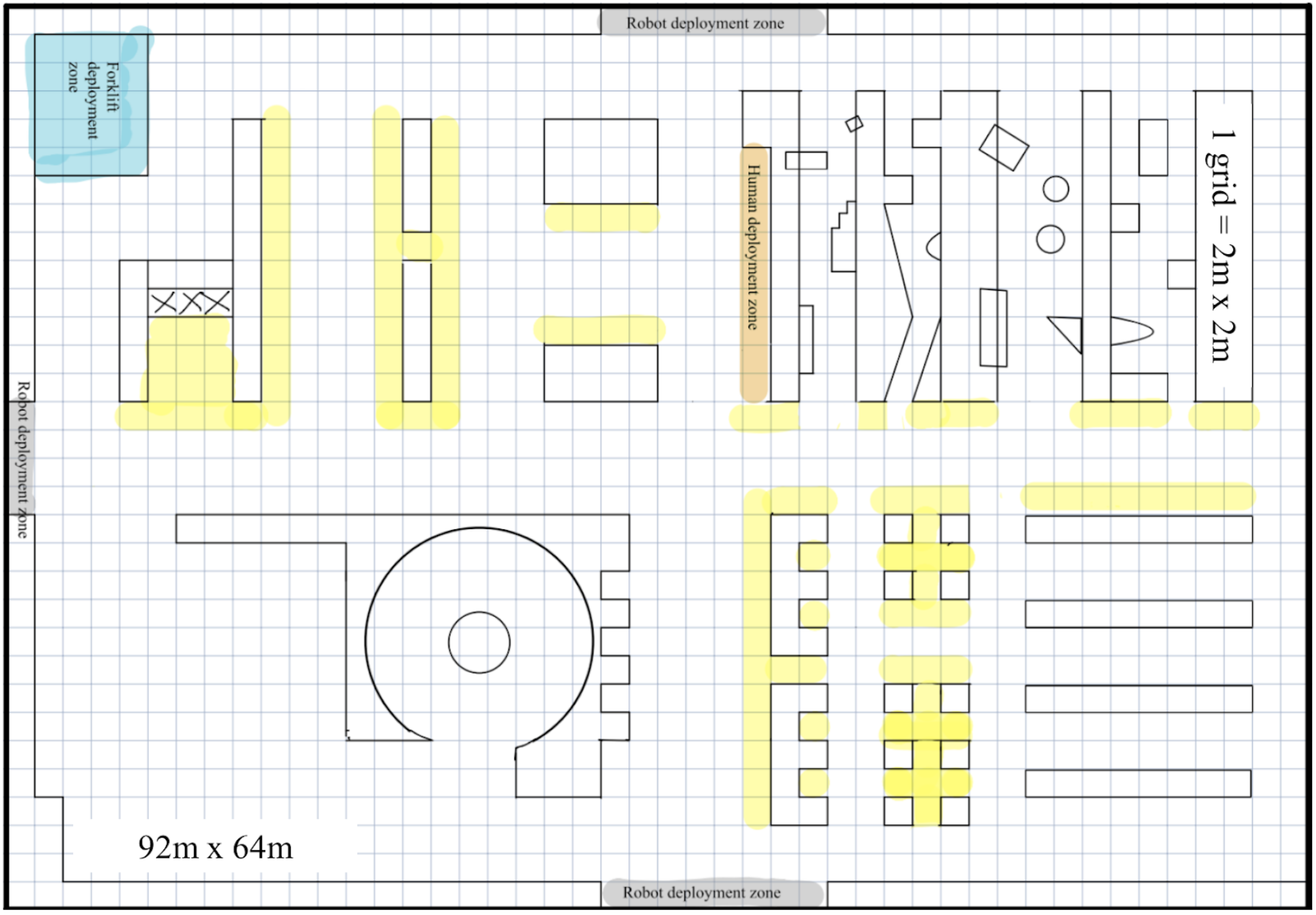

- Operating area: Simulated 92*64 m factory environment (virtual)

Figure 1: Floor plan for the virtual factory environment

B. Procedure:

- The user starts ROS core and simulation

- Simulator loads the floor plan for the factory, and launches the visualization tool.

- Simulator launches pedestrians and forklifts, following their fixed paths and routines

- Simulator launches one robot, and publish waypoints and the static map to robot

- Robots plan global paths and start moving

- Robots continuously receive localization and noisy obstacle observation from simulator

- Robots avoid obstacles according to its predicted trajectories of obstacles

- System stops after a certain duration of time

C. Objective & Requirements to Demo:

- To demonstrate the simulation system and simulated environment with obstacles

- To demonstrate the robot’s ability to plan paths and follow them

- To demonstrate the predictive avoidance algorithm (showing robots dodging obstacles using predicted trajectories)

- To validate M.P.1-3: Robot speed will be above 0.5m/s and below 1.8m/s if no obstacle is detected

- To validate M.P.5: Robots should receive localization and observation in at least 10 Hz, and send back control signals to the simulator in at least 10 Hz

Fall 2021

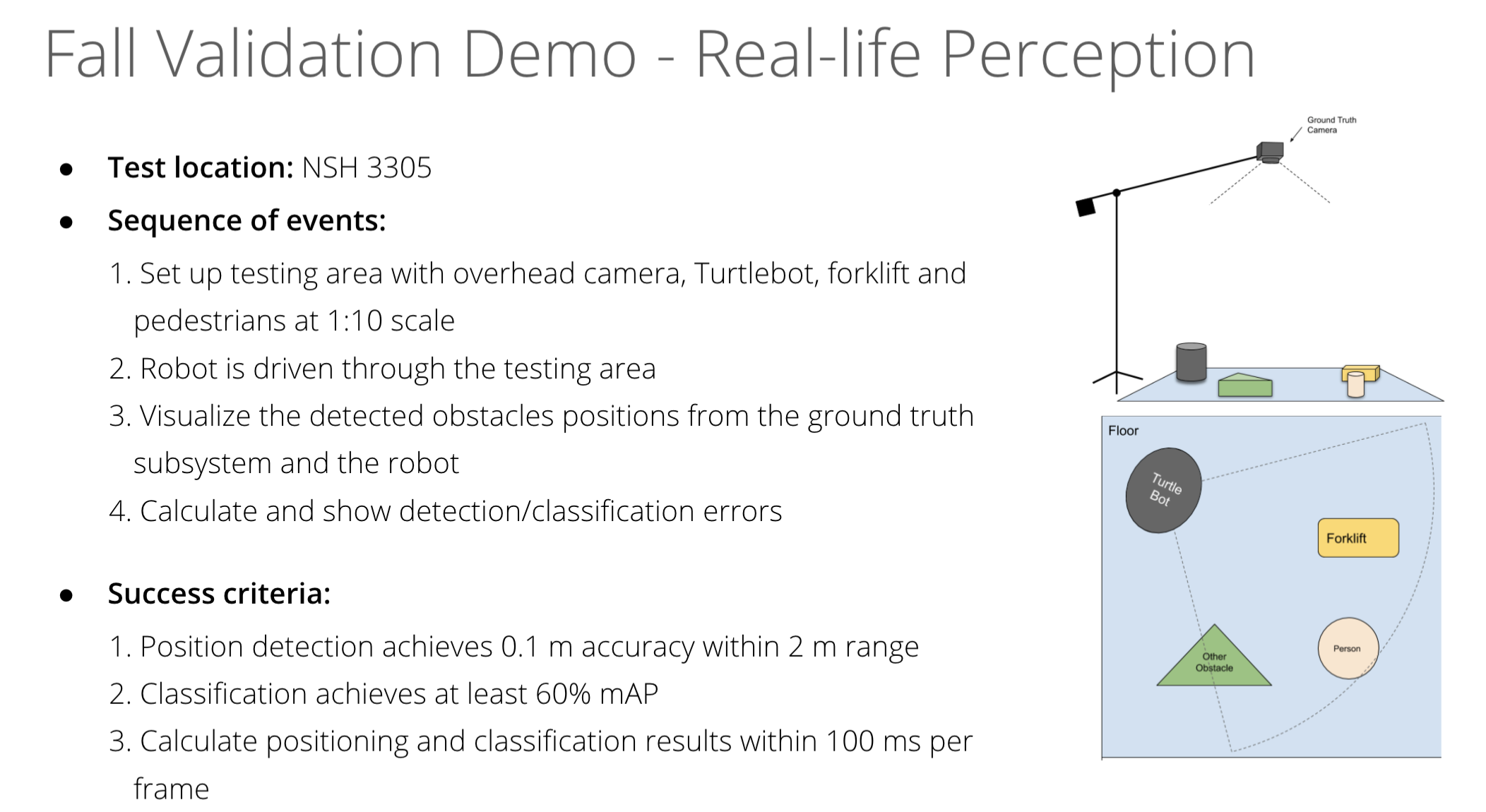

Real-Life System Validation:

A. Demo Conditions:

- Location: Any location with flat ground, sufficient lighting and high enough ceiling (over 2.5 m).

- Equipment: TurtleBot, obstacle action figures/toys, overhead camera, lights

- Operating area: 2*2 m flat ground

B. Procedure:

- Setup overhead camera and place markers on top of robot/obstacles for ground truth gathering

- Place robot and one or more obstacles in testing ground

- Manually drive robot and/or obstacles

- Obtain robot estimation of obstacle positions and classifications for demo duration

- Obtain ground truth position data of robot and all obstacles from overhead camera readings for demo duration

- Use measurement and ground truth data for visualization/plotting

- Evaluate detection (position) and classification accuracy

C. Objective & Requirements to Demo:

- To Validate M.P.6: Classify obstacles of interest with mAP of at least 60%

- To Validate M.P.7: Detect positions of obstacles of interest within 0.1 m accuracy

- To Validate M.P.8: Detect obstacles of interest within a range of 3 m

- To Validate: M.P.9 Output results of positioning and classification within 100 ms per frame

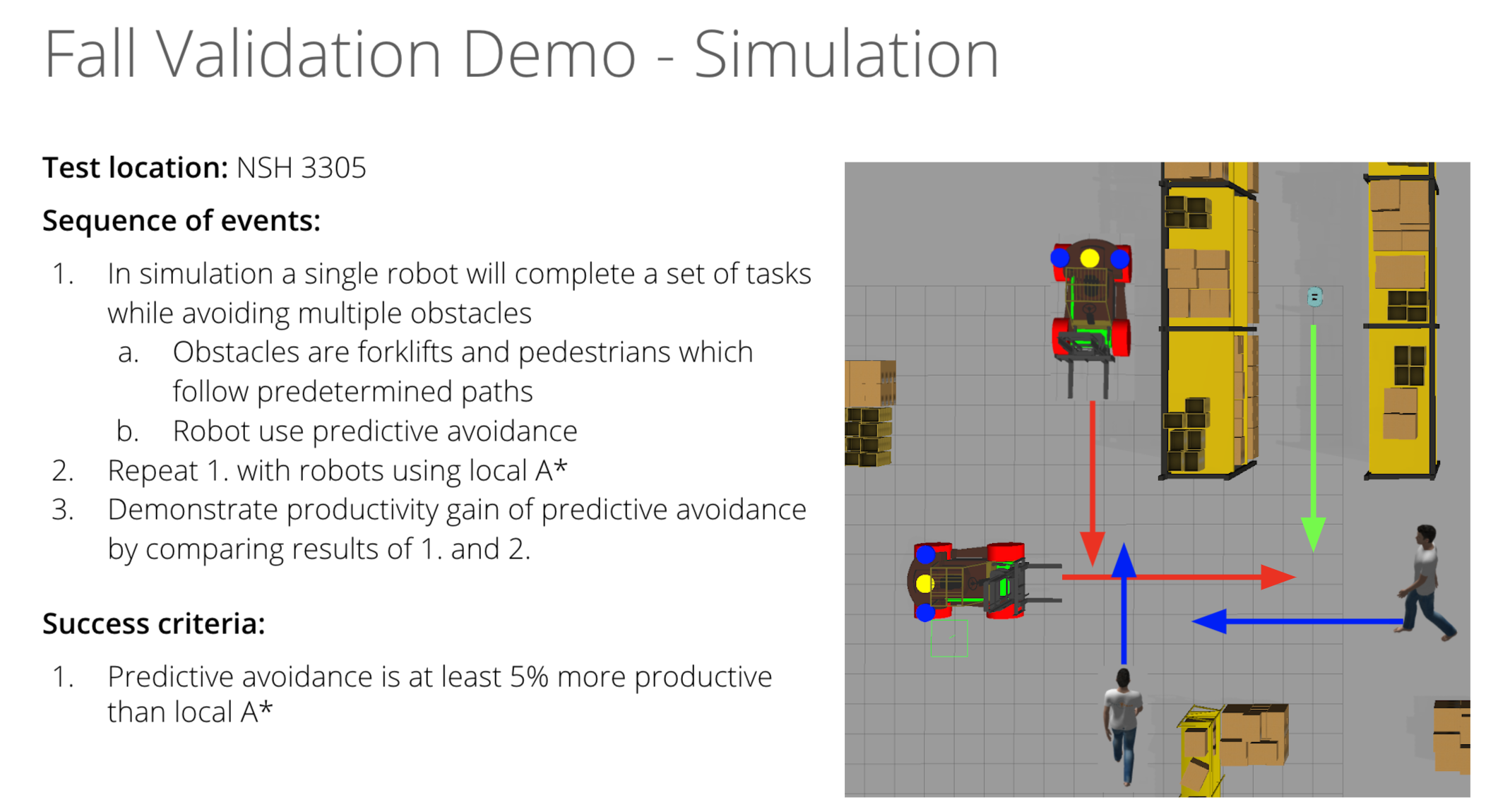

Virtual System Validation:

A. Demo Conditions:

- Location: In simulation

- Equipment: A computer system or cloud server with Gazebo, ROS and COLA predictive avoidance packages installed

- Operating area: Simulated 92*64 m factory environment (virtual)

B. Procedure:

- The user starts ROS core and simulation

- Simulator loads the floor plan for the factory, and launches the visualization tool.

- Simulator launches pedestrians and forklifts, following their fixed paths and routines

- Simulator launches robot fleet, and publish waypoints and the static map to robots

- Robots plan global paths and start moving

- Robots continuously receive localization and noisy obstacle observation from simulator

- Robots avoid obstacles using all three avoidance algorithms

- System stops after a certain duration of time and calculates resulting productivity

- System repeats the previous steps in naive avoidance mode without any classification and prediction, and computes nominal productivity

C. Objective & Requirements to Demo:

- To demonstrate all three avoidance algorithms (predictive, conservative, reciprocal)

- To validate M.P.4: Robot fleet should have productivity increased by >5% when using classification-based predictive/reciprocal avoidance compared to nominal productivity using only naive avoidance

- To validate M.P.5: Robots should receive localization and observation in at least 10 Hz, and send back control signals to the simulator in at least 10 Hz