The FVD demonstration will need all 5 members of the team to be present and will take place outside the cage. The Hello Robot, operator’s computer, customized tools, and the test setup will be needed for the demonstration.

Procedure

- The environment will be set up with two rows each of 3 meters in length covering a square of 3 m by 3 m as shown in Figure 1.

- About 10 to 15 tomato clusters of varying sizes will be placed on the rows at random locations.

- The robot will be placed at the initial location and the nodes loaded into ROS.

- The behavior planner will be requested to start the harvesting procedure.

Figure 1. FVD Farm Layout

Validation

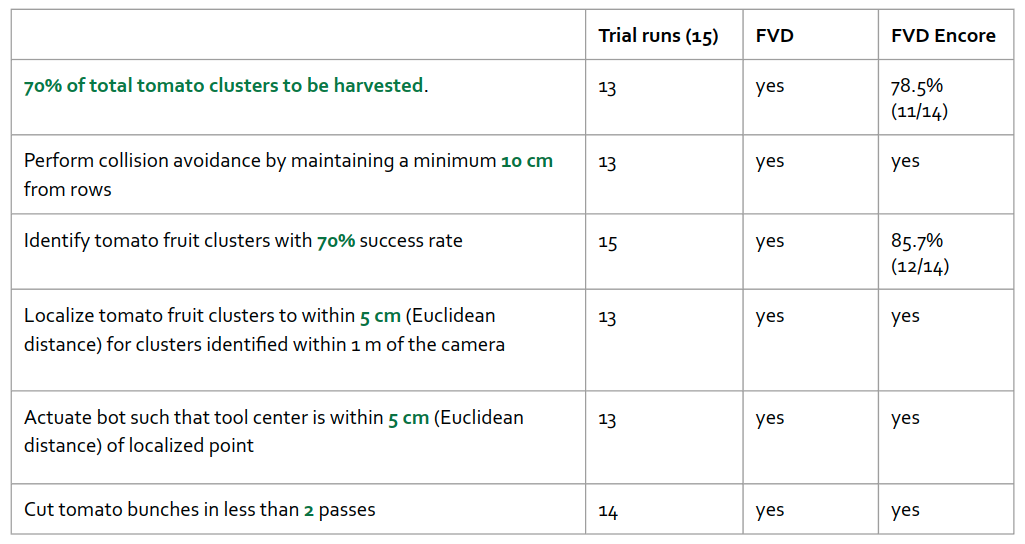

The robot should traverse the farm layout without interference with the farm rows, stop at the correct tomato cluster goal locations and harvest the tomato clusters. A successful completion would require 70% of total tomato clusters to be harvested. Sub-system performance will be evaluated in the visualizations in RVIZ where detected clusters, manipulator and cutter frames will be visualized. (M.P.1, M.P.6, M.P.7, M.P.8, M.P. 9, D.P.2)

Performance