The Problem

The past few years have witnessed the rise of several new indoor farming processes primarily bolstered by advances in lighting technology and control, hydroponics, and automation. While these new processes promise improved yields and lower consumable costs compared to legacy farming methods, there is still much that holds them back. Two common roadblocks often encountered in the implementation of indoor farms is the lack of natural pollination agents indoors and labor-intensive harvesting seasons. Both of which involve high costs and rigorous manual labor.

The Solution

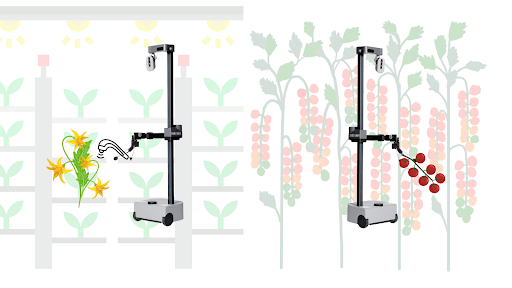

This is where our team, Bob the Farmer, comes in. Our goal is to develop a robot based on the Hello Stretch RE1 platform that can do both harvesting and pollination for tomatoes (Fall update: Focussing on harvesting!). The platform is well suited to the task with a mobile base that is designed for traversing indoor environments coupled with a simple manipulator that can handle most farm activities without the added complexity of an entire robotic arm.

Our robotic system will make use of custom-designed harvesting and pollination tools (Fall update: Focussing on harvesting!) while autonomously navigating around the farm, identifying interaction sites, and performing the desired action. All with minimal human interaction except for the option of a manual override in order to circumvent unexpected risks.

The Future

Tim owns a 900×1260 sq ft indoor vertical farm, where he grows organic, pesticide-free cherry tomatoes. This is not easy- a lot of work is involved for seeding, pruning, pollinating, harvesting, and maintenance- all year round. As the pandemic hit, Tim’s labor force was cut down from 15 to 4. This reduced productivity of the farm and they were behind schedule – leading to more losses. Tim then conferred with his staff and decided to buy BTFv7, an autonomous robot specially designed for indoor farming.

The BTFv7, when on-farm, extensively took over the harvesting and pollinating process. It first scanned the farm, identified the flowers, and then started the pollination process. Tim just had to provide the tool and the starting position to the robot – everything else was managed by BTFv7. In the harvesting season, BTFv7 was again brought out, given the required tools and start position. Harvesting by the robot took a somewhat similar time to what humans took- but it was so much more efficient! the best part was that the BTFv7 could work closely with humans so that both human and robot processes could go in parallel.

As the farming cycle completed, Tim realized that he had increased his yield by 30% and profits by 50%. He also reduced labor costs and made the entire process so much more sustainable, saving up on power and water!

The Project Scope

Our goal is to develop a robot based on the Hello Stretch RE1 platform that can pollinate and harvest tomatoes (Fall update: Focussing on harvesting!).

Our robotic system will:

- Make use of custom-designed tools.

- Autonomously navigate around the controlled setup environment that mimics a vertical farm

- Identify the interaction sites where the task must be performed

- Perform the desired harvesting and pollination action. (Fall update: Focussing on harvesting!)

These tasks will be performed with minimal human interaction except for the option of a manual override in order to circumvent unexpected risks.