The test environment was set up with the intention of mimicking an actual tomato green house as accurately as possible. A standard single tier clothing rack with wooden boards at the base were used to create a single row element of the farm. Each clothing rack can support about two to three plant pots with two plants per pot. Fig. 1 shows the test setup when stowed inside the caged area of the NSH Basement.

Since the maintenance of the plants and the test environment is itself a time consuming task, it was decided to install automatic water pump systems and automated grow lighting. Fig 2. shows the automatic pump and tank system that was put in place. The automatic pump allows for significant water savings since we can fine tune the delivery to exactly what the plant needs and no more.

Fig 3. shows the automatic grow lights that are continuously adjusted along the length of the clothing rack as the plant grows. As per the recommended guidelines for tomato plants, these full spectrum lights run for 16 hours a day providing artificial light to the plants.

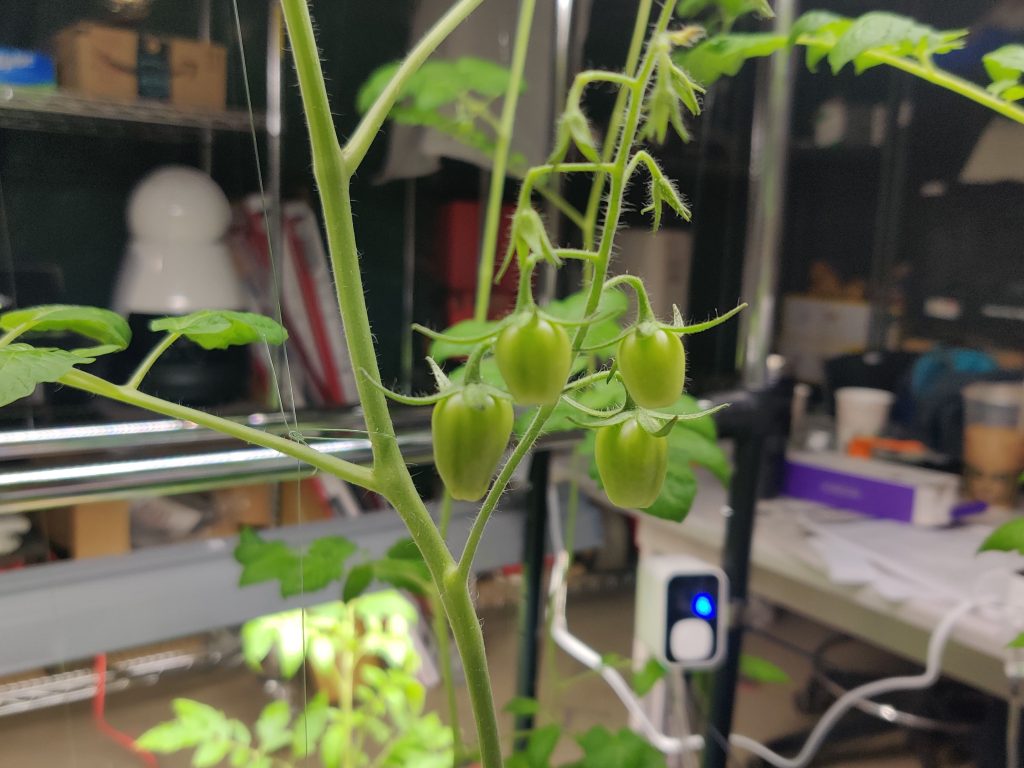

The first batch of plants seeded in November of 2021 ave begun to bear flowers and bear fruit. New flowers are promptly pollinated artificially. Fig 4. shows the first batch of fruits that are expected to ripen by mid-March 2022.

Fall update

Previous Status:

- Real plants withered over the summer

- Unreliable availability of tomatoes on demonstration days

- Upkeep in itself a project

Current Status:

- New plant stems made from floral wire

- Foliage created using fake vine leaves to recreate same noisy backdrop

- Reduces need for upkeep