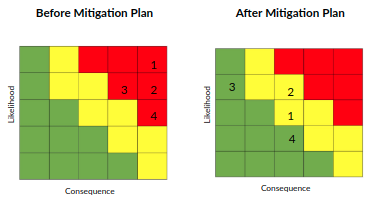

After exploring the design, schedule, resources associated with our project, some of the major risks have been outlined in Table1. Our technical risks include parts of the robot failing, subsystems being insufficient to complete the functional requirements associated, and the inability to produce a test setup with the intricate features needed.

Updated Risks – December 2022

| No. | Risk | Category | Description | Likelihood | Consequence | Mitigation Plan |

| 1 | Arm Translation | Technical/Schedule | The robot arm does not move to the desired location at all times | 5 | 5 | Recalibrate the armInclude base motionReach 3D point step-wise |

| 2 | Tool extension not working | Technical/Schedule | The wacc extension is sensitive and if it is spoilt, the tool extension stops working ;The tool motors sometimes operate with reduced torque | 4 | 5 | Have wacc replacements in stockAdd the tool as an end-of-arm class so it operates with greater torque |

| 3 | Jetson network issues | Technical | The current Jetson seems to have some network issues | 4 | 4 | Alternate Jetson ready to be ported |

| 4 | Lack of communication within team | Personnel/Technical | Subsystem-wise developments are not communicated and integration is affected | 3 | 5 | Weekly meetingsWork sessionsCritical decisions documentedSubsystems in pairs |

| Risk# | Risk Title | Mitigation | Category | Likelihood | Consequence | Indicator |

| R1 | Intel D435 camera on robot fails | – Buy backup D435 camera – Shift to simulated testing while the camera is being fixed | Technical, schedule, cost | 2 | 4 | Medium |

| R2 | The end effector gets stuck when trying to interact with the vines. | – Design the tool to have a quick disengagement lock/mechanism that is activated when a tilt is sensed. – Have a teleop manual override in case of failure | Technical, cost | 4 | 5 | High |

| R3 | Inability to reproduce the test environment for pollination | – Find a similar plant-like yellow lilies – Grow 30 plants for final testing purposes | Technical, schedule, cost | 4 | 4 | High |

| R4 | Perception system camera range is not sufficient | – Fix another camera on/ near the end effector of the robot – Camera can be fixed on the farm setup for more visual feedback | Technical, cost, programmatic | 4 | 3 | Medium |

| R5 | Team Member gets held back/isolated in a different locality due to the advent of the omicron variant. | – Schedule regular meetings for effective information distribution – In-person tasks can be delegated to another member – Utilize collaboration tools | Schedule, programmatic | 2 | 2 | Low |

| R6 | Flooding in the basement causes harm to the stretch robot, test setup | – Have a backup area ready for shifting test setup – Make test setup modular for easy transportation – Always keep stretch robot at a minimum height of .75 m from the ground when not in use | Technical, schedule, cost | 4 | 4 | High |

Detailed versions of the risk tables can be seen in Fig 1- Fig