Risk Management

End-of-Project Risk Management Update

Fortunately, most risks that we foresaw in the Fall 2022 Semester did not come to fruition. The only risk that did affect us was not fully meeting performance requirements for FVD. More specifically, all but one requirement was met, and that one was to ream the bone with a 2 mm max error. This consequence was unfortunately because of small tolerance stack-ups in our system, with the most significant error source from the flexibility of the Kinova Gen 3 Arm itself. Unfortunately, because of a lack of budget, time, and feasibility of swapping to a less flexible arm, we were unable to mitigate the extra tolerance in our system. However, despite this shortcoming, we were able to hit this goal 2 out of 5 times, and were only 1.4 mm out of spec at maximum.

Fall 2022 Risk Management

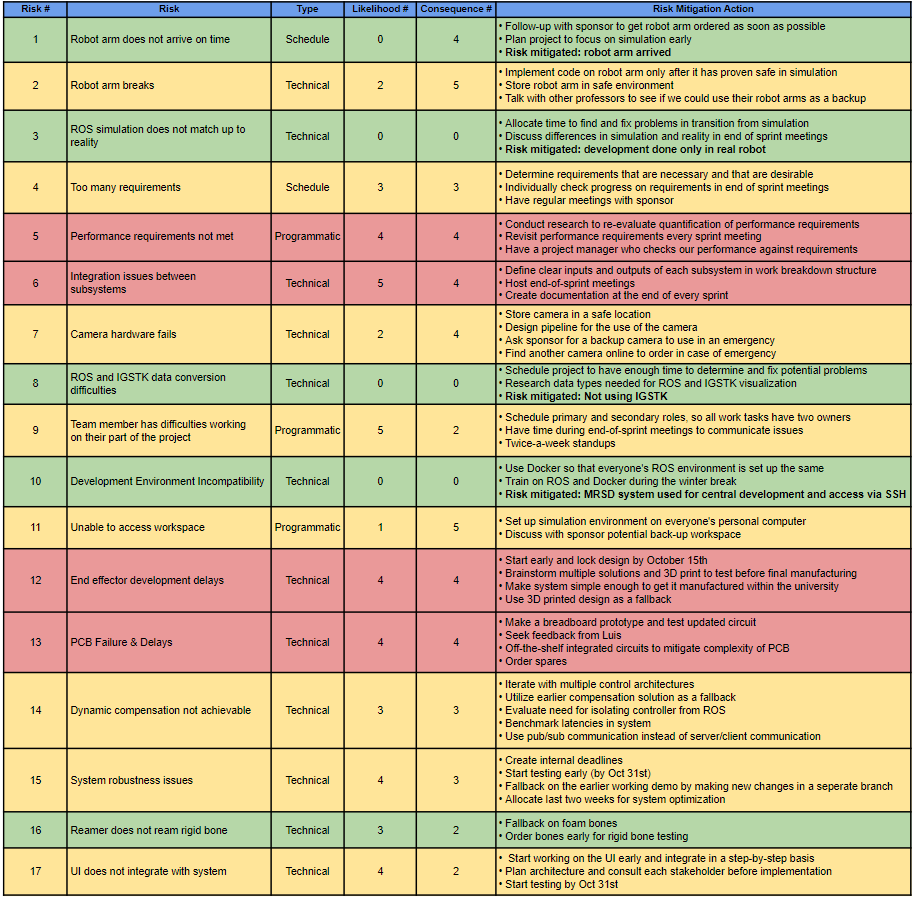

Risk Management Table and Likelihood-Consequence Chart

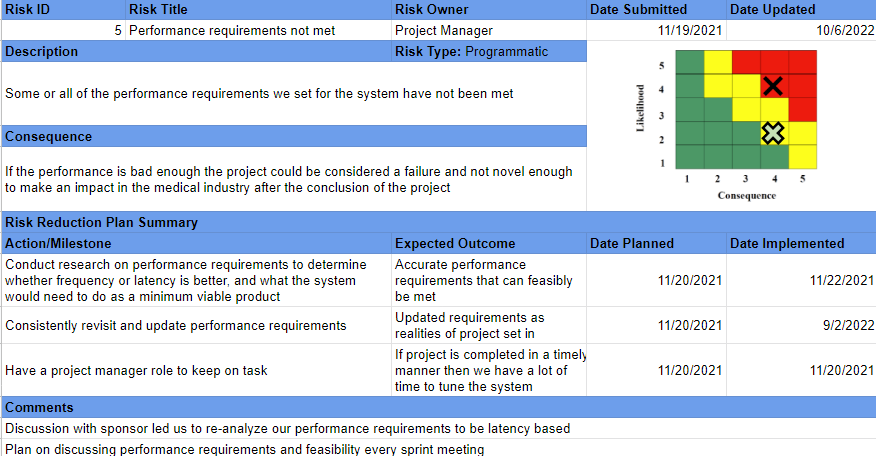

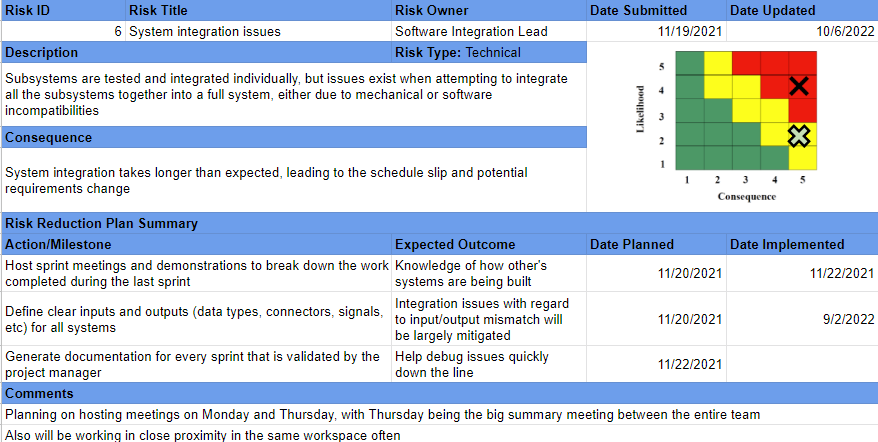

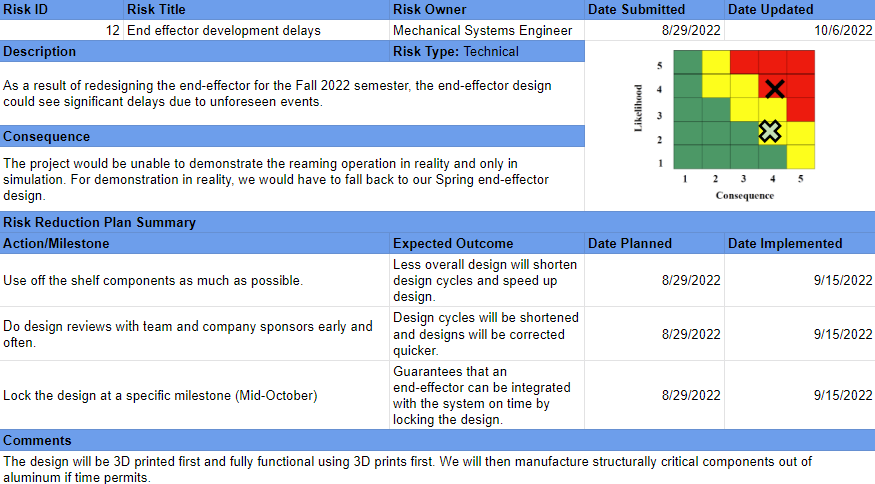

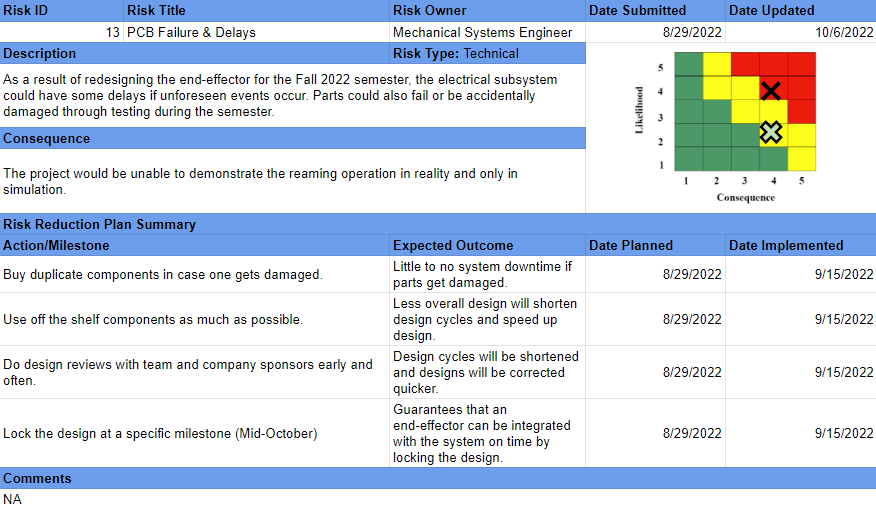

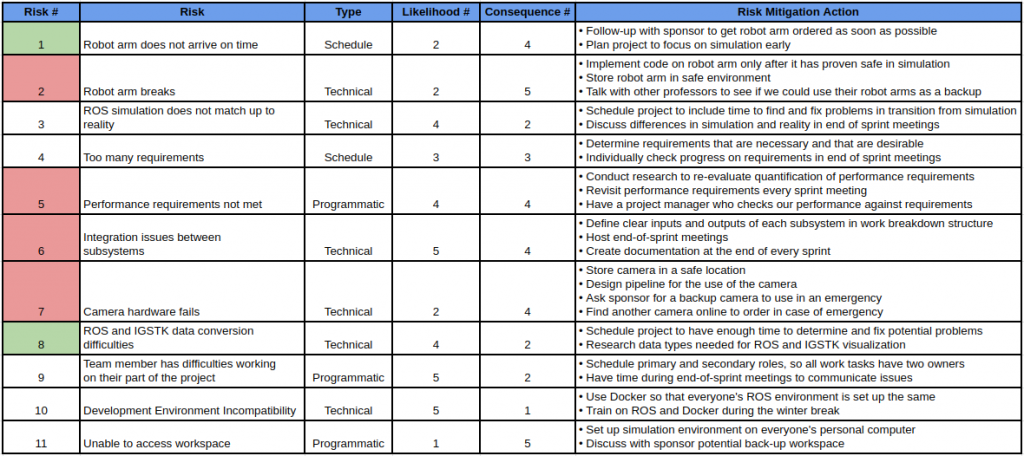

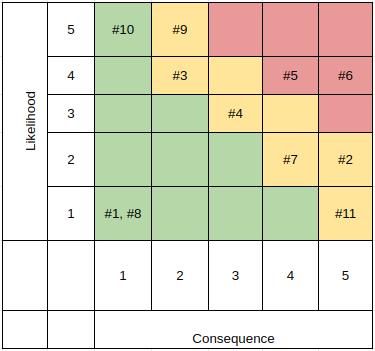

With the new system requirements and modified subsystems, new risks were also added into the project, not only for the system as a whole, but also within each subsystem and delays associated with each subsystem. A summary of risks can be seen below. Several risks from the Spring 2022 semester have already been mitigated.

Details on Five Biggest Risks

Spring 2022 Risk Management

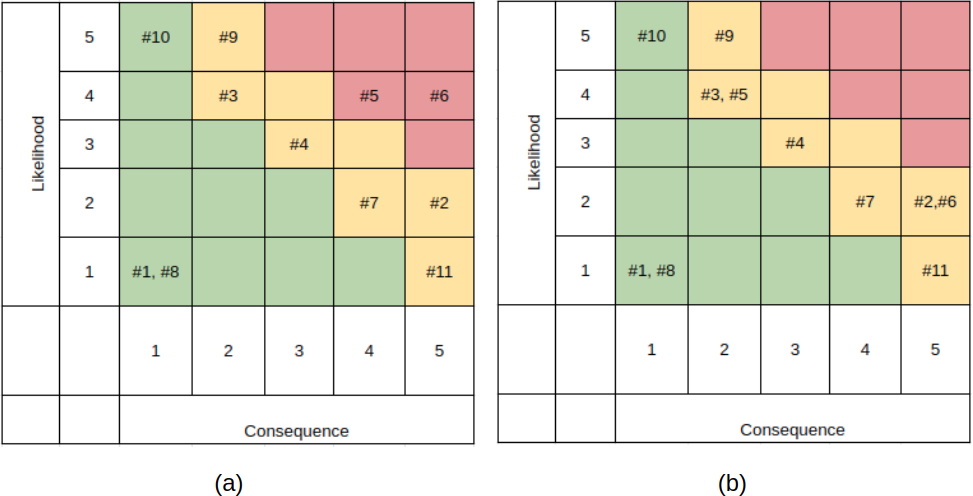

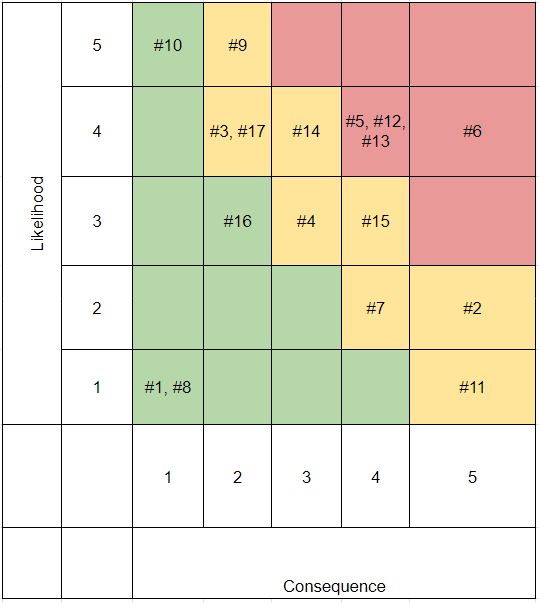

Risk Management Table and Likelihood-Consequence Chart

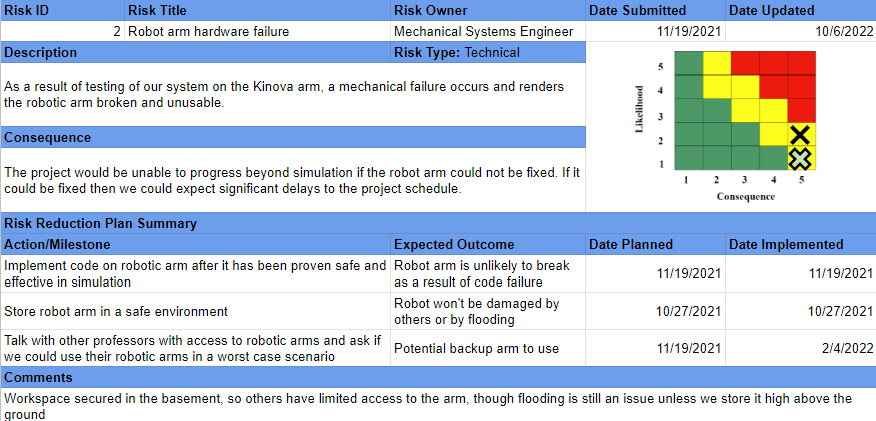

Details On Five Biggest Risks

End of Spring 2022 Update:

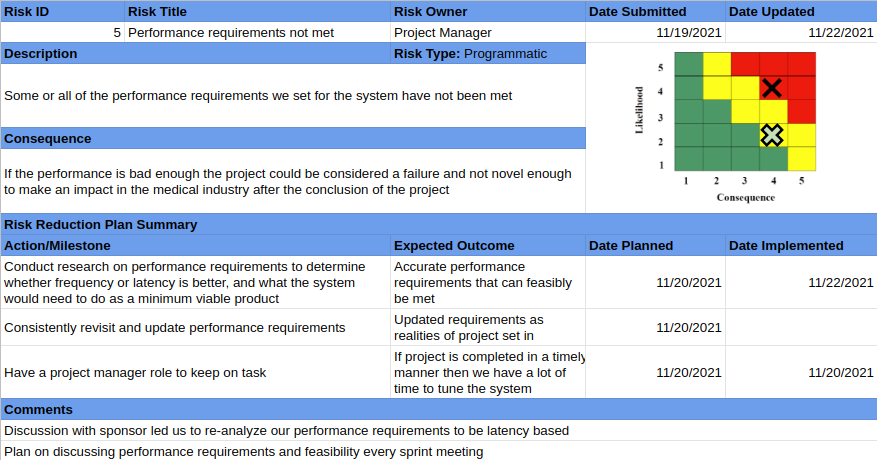

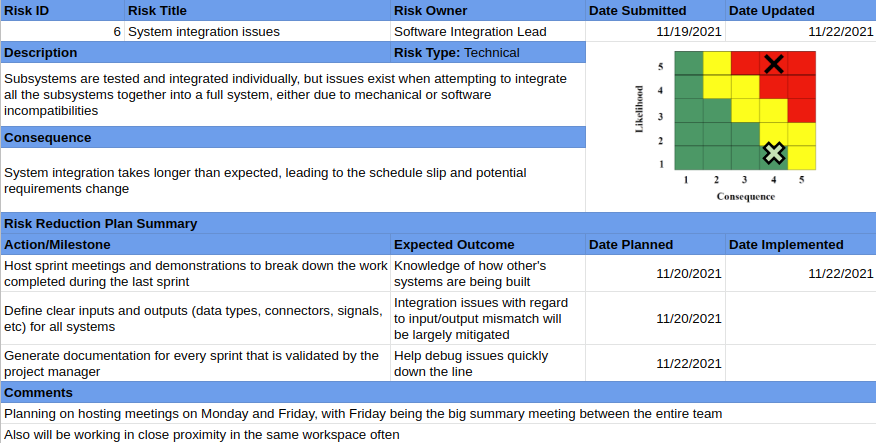

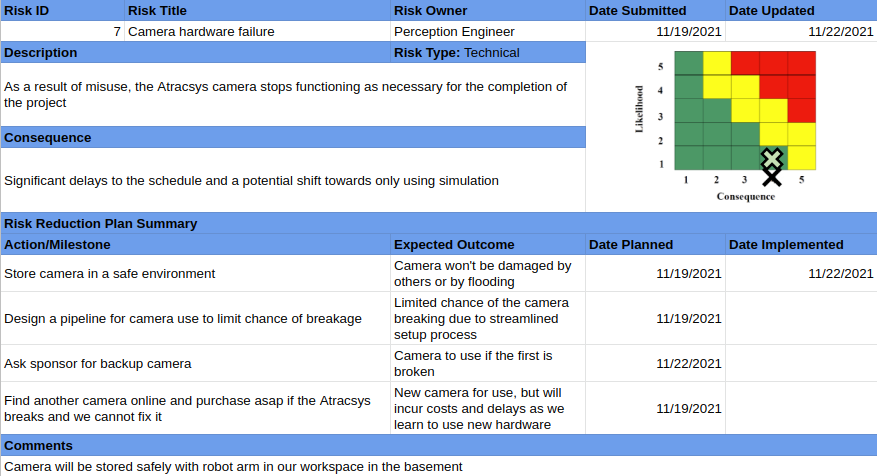

There are many technical, schedule, and programmatic risks that could adversely effect the team’s capability to complete the project successfully, all of which are summarized in the Risk Management Table.

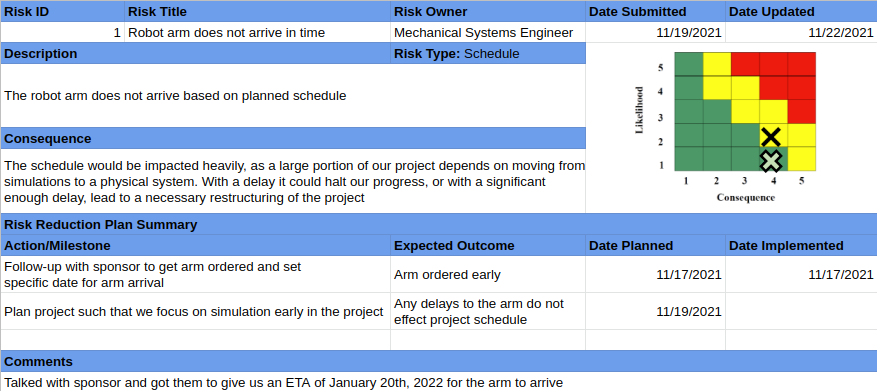

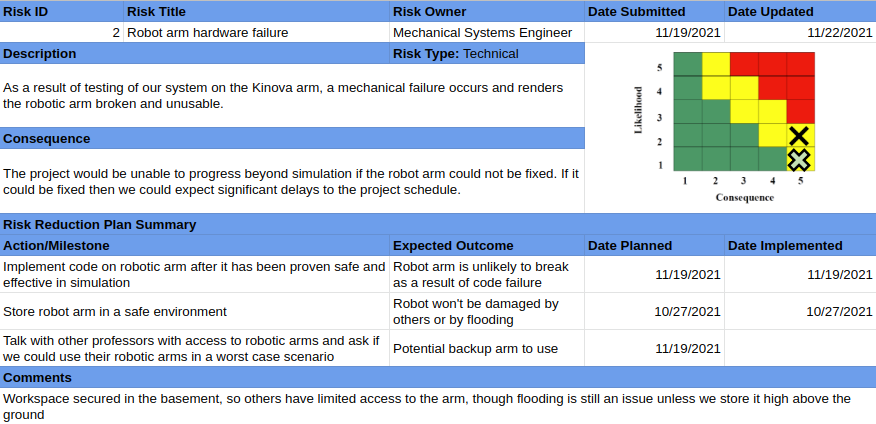

From the risks listed in the table, we realized the risk of the robot arm not arriving on time. This risk could have caused significant delays and major re-scoping of the problem statement if we had not done our due diligence as part of the Systems Engineering course. Below are the effects and the mitigation strategies applied:

Risks realized:

- The Link-6 arm from Kinova arrived on Feb 5th, as opposed to the expected date of Jan 20th.

- The Link-6 had deficiencies in its software capabilities and could not be integrated with ROS, which was a crucial factor in our system performance.

- The Kinova Gen3 arm arrived two weeks after us returning the Link-6 to our sponsors, leading to a total delay of 4 weeks in receiving the arm.

Mitigation Steps:

- We started developing our sub-systems in simulation, which helped us to continue working on the project and also helped us evaluate the performance of each system before integrating it in reality.

- Frequent and clear communication with our sponsors proved crucial in getting a replacement arm in Gen3, without which meeting our requirements would have been tough.