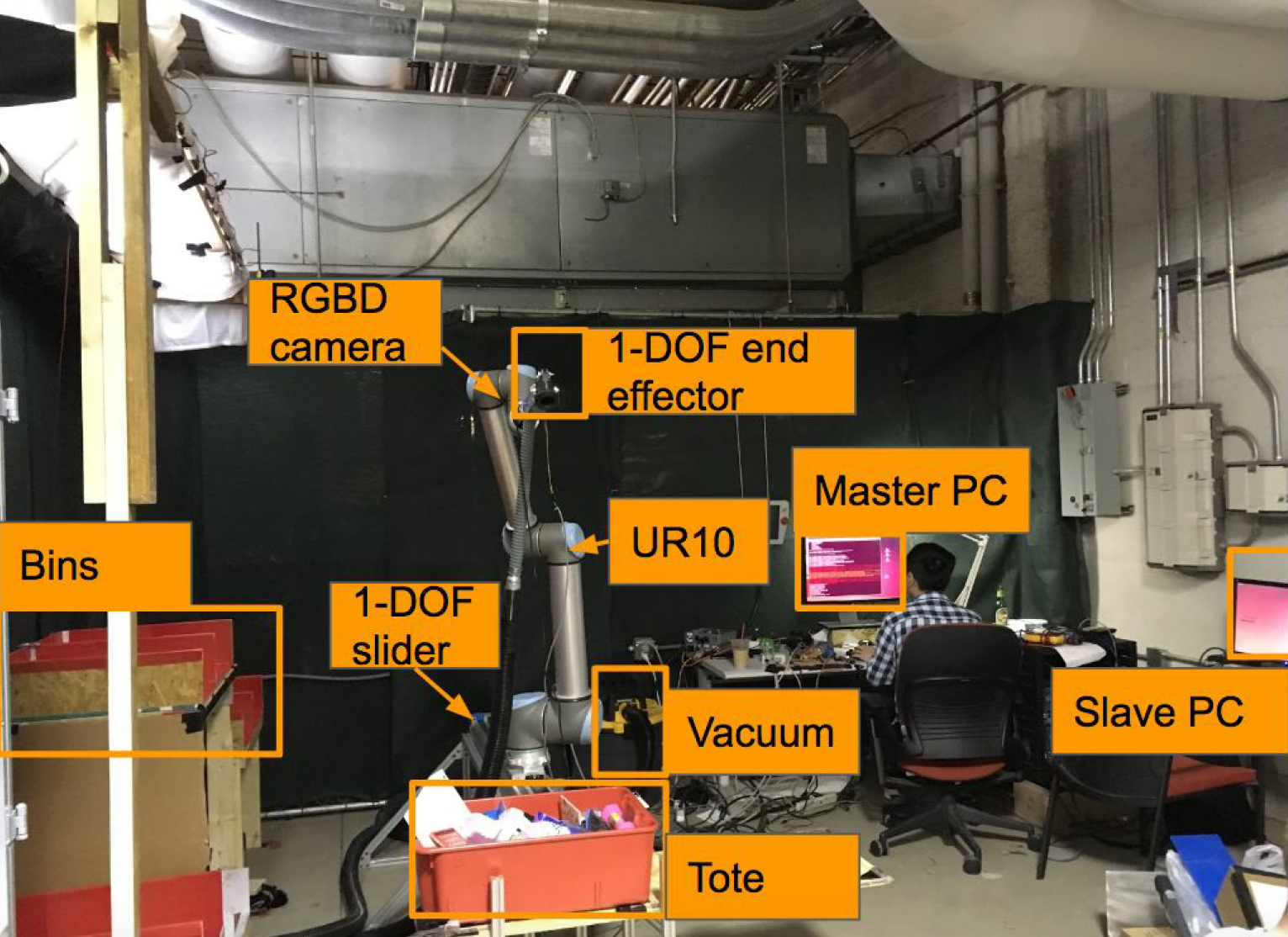

System Hardware

The robotic arm being used for the system is a UR10. The arm uses a raised 1-DOF slider in order to reach all bins. The suction gripper is installed and operational, utilizing a construction-job style shop vac for its flow generation. The suction gripper offers an extra degree of freedom with 90 degree rotational functionality. The shelf, which will eventually be constructed of aluminum and steel, is currently fabricated from wood and operational for this project’s purposes. The system is using a master-slave server setup, with 2 CPU’s and 4 GPU’s total. The entire system setup can be seen in the following image.

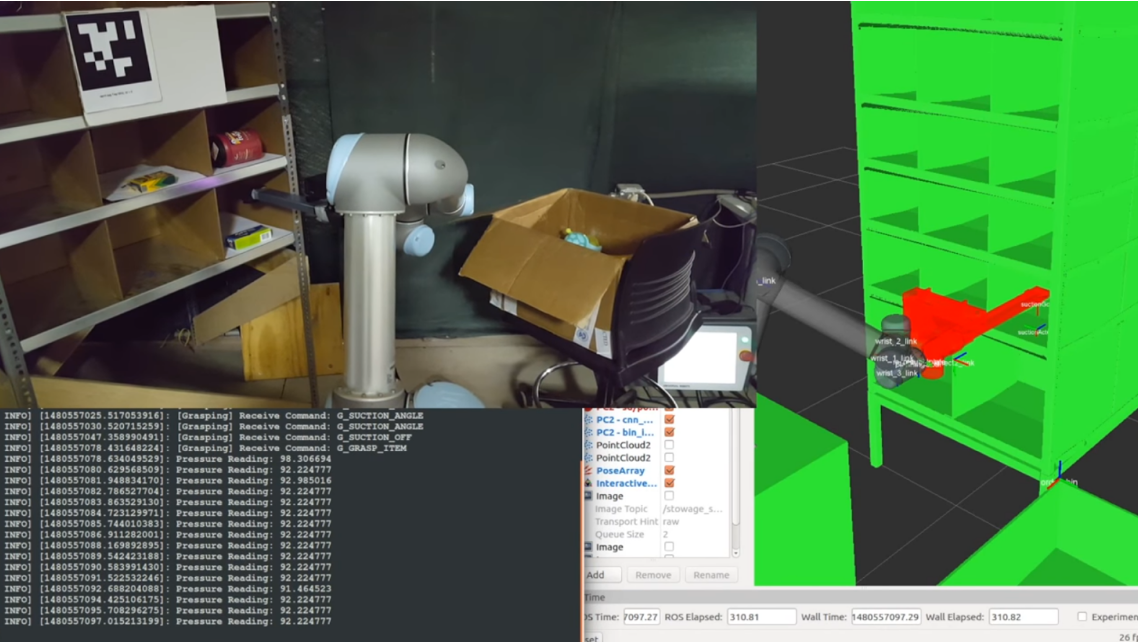

First Iteration of Design

This is a composite image which shows that multiple subsystems are working correctly in tandem to perform a successful pick. On the right the image, the collision model for the planning subsystem is shown. In the lower left corner, pressure feedback from the grasping subsystem is being printed to the terminal. To execute a pick, the grasping system uses data from the perception system to send movement requests to the motion planning system. Higher level decisions are made by the robot’s state machine. While the subsystems are implemented in a simple way, their integration is complete.